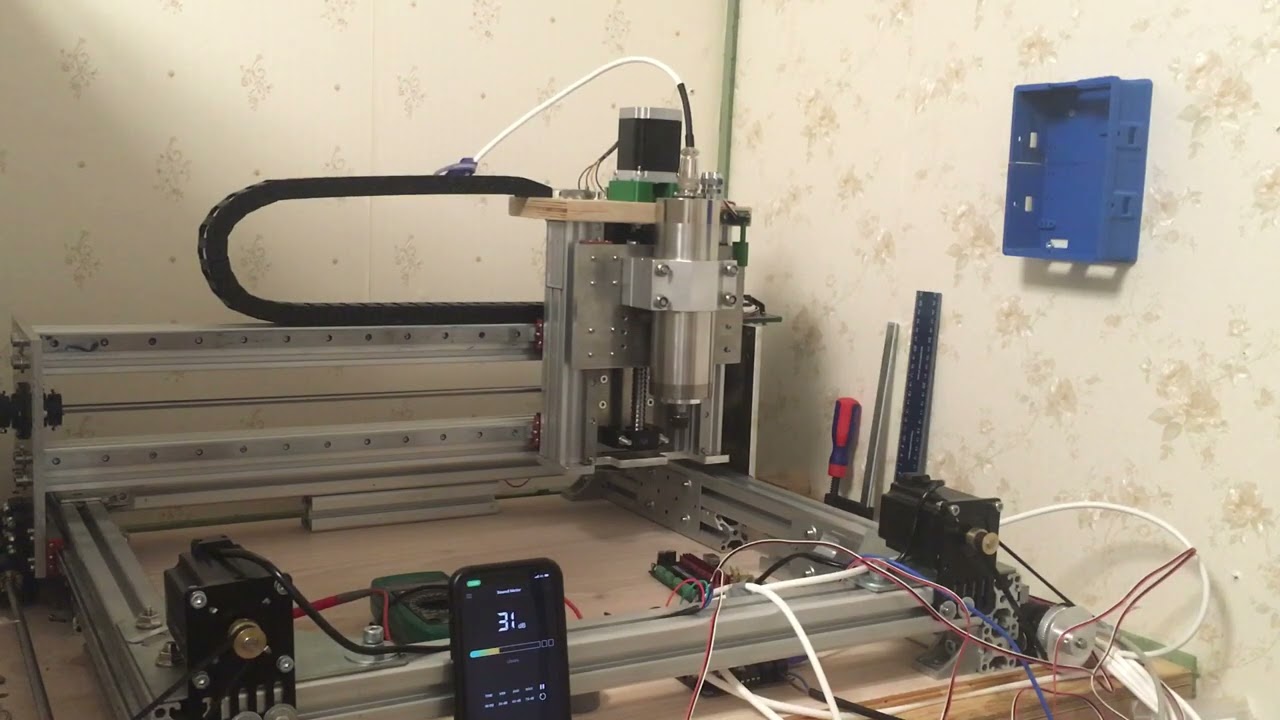

@nikolaewich1988

Its weird, 720mm/min seems like a magic number for TMC stepper drivers running NEMA23. I had some issues with the motors stalling at higher speeds. So I took off the belt and ran the motor at the same speeds and the stall still happened around 500 mm/min (4:1 gearing). Then I disabled StealthChop, and now I can achieve 720mm/min without stalling but with considerable louder motors ? In Marlin there is a #define HYBRID_THRESHOLD setting, I might try that.

These issues, should in theory be non-existing in a FOC driven stepper, if the MCU can handle the calculations and the bridges are fast enough, combined with a good 14bit encoder or some clever BEMF circuit.

Edit: mm/min not mm/s

Since my setup is geared 4:1 with a 8mm pitch lead screw one rotation from the stepper is 2mm which translated to a max rpm 720mm/min / 2mm = 360 rpm… (770mm/min starts to cause the issue, so running my TMC2660 at max 30v (Max) could most likely reach a 25% increase.

Maybe this is related to inductance ?

For future reference, this one had the same issue and found that upgrading from 24v to 36 did the trick… Stalling RPM for High Torque Stepper? | OpenBuilds

In that regard, then going for TMC5160, which dependent on FETs, can tolerate 60v, would make a huge difference. But still open looop and probably not with StealthChop at those speeds. Then the limiting factor is suddenly the main board voltage rating (most likely caps ratings).

If running a Klipper install on a linux machine or RPi, without a mainboard, but with SimpleFOC stepper drivers, higher voltage would be entirely dependent on the controller design ( FETs, caps etc.). 48v could be a good target voltage for FOC stepper driver, running standard NEMA23 for CNC purposes.

Im starting to understand why one would use TB6600 or create a ESP32 main/sub_driver rated for higher voltage. All though a S-FOC stepper driver will still be awesome…

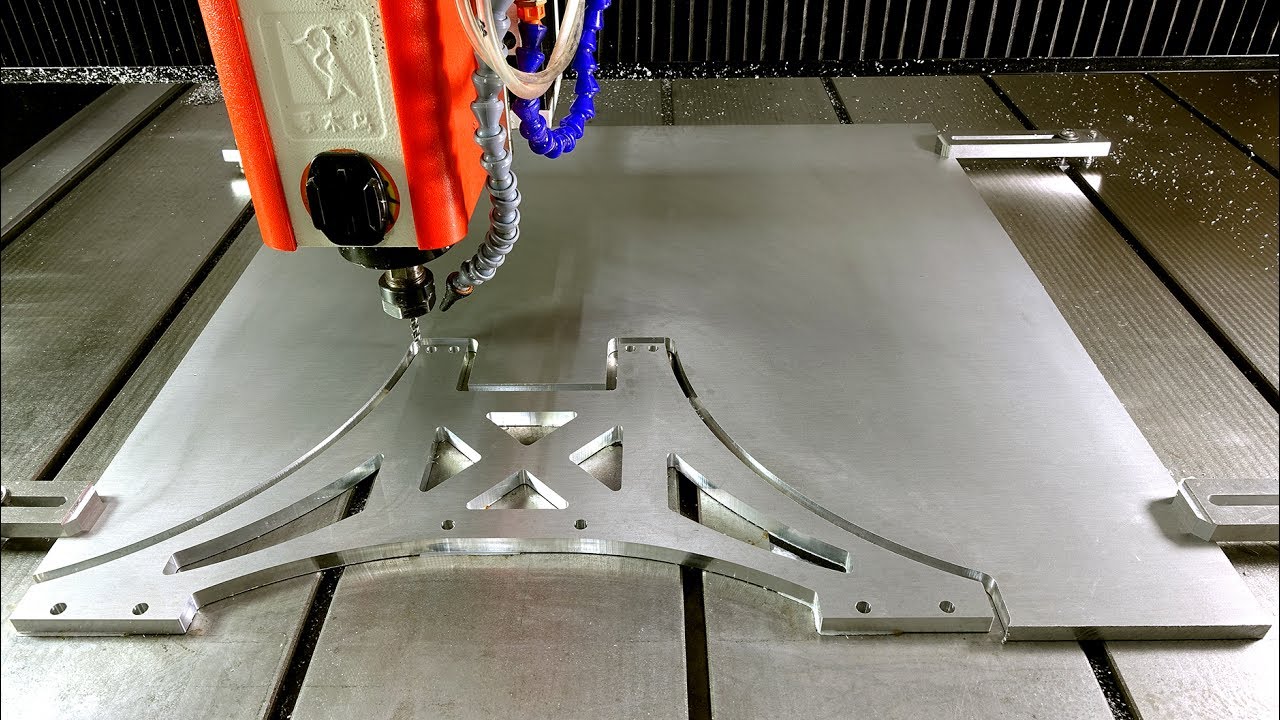

Great educational vid about tools and feed´s for aluminum