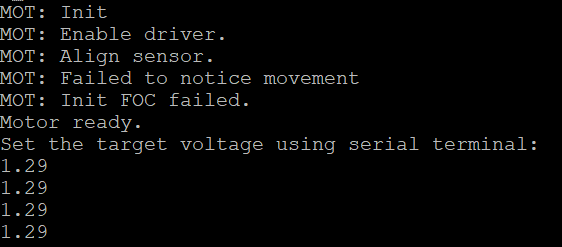

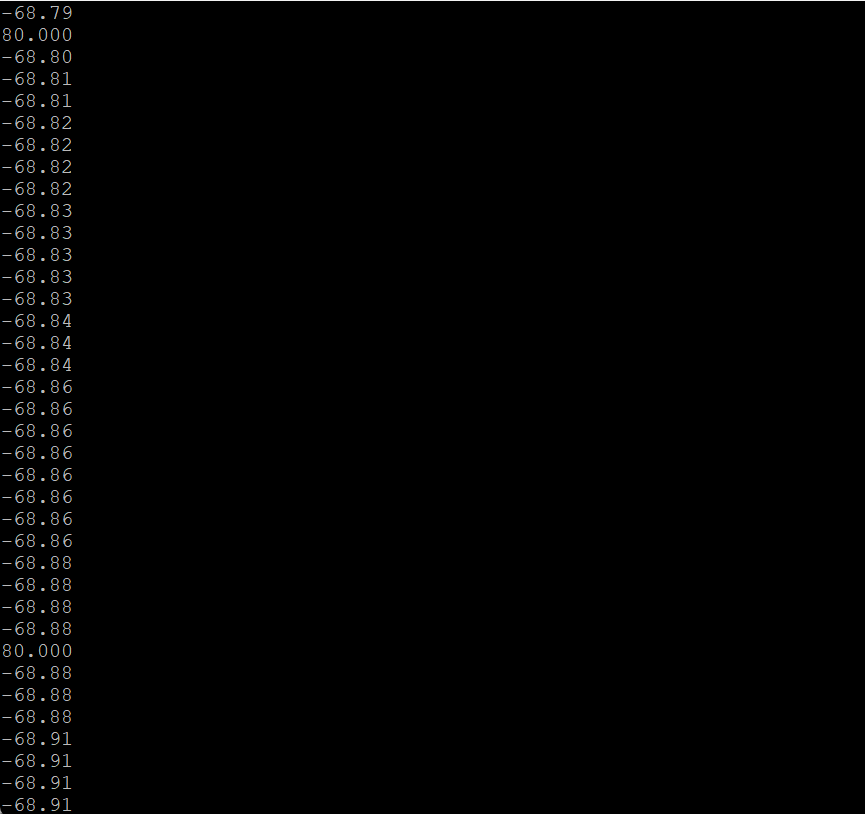

Hello, I am working with a STM32r405 based board and an AS5048 on Arduino IDE. I can get it to work in open loop and the sensor reads correctly, but in closed loop mode it still fails. I put a sensor.getAngle in the main loop and It shows the correct values, but it fails to calibrate and if I skip calibration with hard coded values it just jerks and stays still. I don’t know why the library seems like it cannot use the sensor values. please help.

Code:

{

/**

* Torque control example using voltage control loop.

*

* Most of the low-end BLDC driver boards doesn't have current measurement therefore SimpleFOC offers

* you a way to control motor torque by setting the voltage to the motor instead hte current.

*

* This makes the BLDC motor effectively a DC motor, and you can use it in a same way.

*/

#include <SimpleFOC.h>

#include <Arduino.h>

#include "SPI.h"

//#include <Wire.h>

#define HSE_VALUE 8000000

// from STM Cube-IDE, Clock config

//extern "C"

void SystemClock_Config(void)

{

RCC_OscInitTypeDef RCC_OscInitStruct = {0};

RCC_ClkInitTypeDef RCC_ClkInitStruct = {0};

/** Configure the main internal regulator output voltage

*/

__HAL_RCC_PWR_CLK_ENABLE();

__HAL_PWR_VOLTAGESCALING_CONFIG(PWR_REGULATOR_VOLTAGE_SCALE1);

/** Initializes the RCC Oscillators according to the specified parameters

* in the RCC_OscInitTypeDef structure.

*/

RCC_OscInitStruct.OscillatorType = RCC_OSCILLATORTYPE_HSE;

RCC_OscInitStruct.HSEState = RCC_HSE_ON;

RCC_OscInitStruct.PLL.PLLState = RCC_PLL_ON;

RCC_OscInitStruct.PLL.PLLSource = RCC_PLLSOURCE_HSE;

RCC_OscInitStruct.PLL.PLLM = 4;

RCC_OscInitStruct.PLL.PLLN = 168;

RCC_OscInitStruct.PLL.PLLP = RCC_PLLP_DIV2;

RCC_OscInitStruct.PLL.PLLQ = 4;

if (HAL_RCC_OscConfig(&RCC_OscInitStruct) != HAL_OK)

{

Error_Handler();

}

/** Initializes the CPU, AHB and APB buses clocks

*/

RCC_ClkInitStruct.ClockType = RCC_CLOCKTYPE_HCLK|RCC_CLOCKTYPE_SYSCLK

|RCC_CLOCKTYPE_PCLK1|RCC_CLOCKTYPE_PCLK2;

RCC_ClkInitStruct.SYSCLKSource = RCC_SYSCLKSOURCE_PLLCLK;

RCC_ClkInitStruct.AHBCLKDivider = RCC_SYSCLK_DIV1;

RCC_ClkInitStruct.APB1CLKDivider = RCC_HCLK_DIV4;

RCC_ClkInitStruct.APB2CLKDivider = RCC_HCLK_DIV2;

if (HAL_RCC_ClockConfig(&RCC_ClkInitStruct, FLASH_LATENCY_5) != HAL_OK)

{

Error_Handler();

}

}

#define PIN_SERIAL1_RX PA3

#define PIN_SERIAL1_TX PA2

#define SERIAL_PORT_HARDWARE Serial2

HardwareSerial Serial2(PIN_SERIAL1_RX, PIN_SERIAL1_TX);

// MagneticSensorSPIConfig_s AS5047P_SPI = {

// .spi_mode = SPI_MODE1,

// .clock_speed = 500000,

// .bit_resolution = 14,

// .angle_register = 0x3FFF,

// .data_start_bit = 13,

// .command_rw_bit = 14,

// .command_parity_bit = 15

// };

// magnetic sensor instance - SPI

// MagneticSensorSPI sensor = MagneticSensorSPI(AS5147_SPI, 10);

// magnetic sensor instance - I2C

MagneticSensorSPI sensor = MagneticSensorSPI(AS5147_SPI, PA_0);

//MagneticSensorAS5048A sensor(8);

// magnetic sensor instance - analog output

// MagneticSensorAnalog sensor = MagneticSensorAnalog(A1, 14, 1020);

#define ENABLE_PIN PB12

// #define PWMA PC9

// #define PWMB PA8

// #define PWMC PB13

// #define PWMD PB14

// #define PWME PA9

// #define PWMF PB15

#define M0_INH_A PA8

#define M0_INH_B PA9

#define M0_INH_C PA10

#define M0_INL_A PB13

#define M0_INL_B PB14

#define M0_INL_C PB15

// BLDC motor & driver instance

// BLDCMotor motor = BLDCMotor(pole pair number);

BLDCMotor motor = BLDCMotor(7);

// BLDCDriver3PWM driver = BLDCDriver3PWM(pwmA, pwmB, pwmC, Enable(optional));

BLDCDriver6PWM driver = BLDCDriver6PWM(M0_INH_A, M0_INL_A, M0_INH_B, M0_INL_B, M0_INH_C, M0_INL_C, ENABLE_PIN);

// Stepper motor & driver instance

//StepperMotor motor = StepperMotor(50);

//StepperDriver4PWM driver = StepperDriver4PWM(9, 5, 10, 6, 8);

// voltage set point variable

float target_voltage = 0;

// instantiate the commander

Commander command = Commander(Serial2);

void doTarget(char* cmd) { command.scalar(&target_voltage, cmd); }

// void reciveHandle(int Howmany){

// target_voltage = map((float)Wire.read(), 0, 255, -12, 12);

// }

SPIClass SPI_2(PC12, PC11, PC10);

void setup() {

Serial2.begin(115200);

//pinMode(PA0, OUTPUT);

// SPI.setMISO(PC11);

// SPI.setMOSI(PC12);

// SPI.setSCLK(PC10);

// enable more verbose output for debugging

// comment out if not needed

//SimpleFOCDebug::enable(&Serial2);

// initialise magnetic sensor hardware

//sensor.spi_mode = SPI_MODE1; // spi mode - OPTIONAL

//sensor.clock_speed = 1000000; // spi clock frequency - OPTIONAL

sensor.init(&SPI_2);

// link the motor to the sensor

motor.linkSensor(&sensor);

// power supply voltage

driver.pwm_frequency = 40000;

driver.voltage_power_supply = 12;

driver.voltage_limit = 12;

driver.init();

motor.linkDriver(&driver);

//motor.phase_resistance = 1.5;

// motor KV rating [rpm/V]

//motor.KV_rating = 920; // rpm/volt - default not set 920kv ready to sky

// aligning voltage

motor.voltage_sensor_align = 0.5;

// choose FOC modulation (optional)

//motor.foc_modulation = FOCModulationType::SpaceVectorPWM;

// set motion control loop to be used

motor.controller = MotionControlType::torque;

// comment out if not needed

motor.useMonitoring(Serial2);

//motor.zero_electric_angle = 1.466;

//motor.sensor_direction = Direction::CW; // CW or CCW

motor.voltage_limit = 0.5;

// initialize motor

motor.init();

// align sensor and start FOC

motor.initFOC();

// add target command T

command.add('T', doTarget, "target voltage");

Serial2.println(F("Motor ready."));

Serial2.println(F("Set the target voltage using serial terminal:"));

_delay(100);

}

//int pulseWidth = 0;

//int loopCount = 0;

//int v1 = 0;

//int startTime;

//int endTime;

void loop() {

//startTime = millis();

// main FOC algorithm function

// the faster you run this function the better

// Arduino UNO loop ~1kHz

// Bluepill loop ~10kHz

motor.loopFOC();

Serial2.println(sensor.getAngle());

// Motion control function

// velocity, position or voltage (defined in motor.controller)

// this function can be run at much lower frequency than loopFOC() function

// You can also use motor.move() and set the motor.target in the code

//motor.move(target_voltage);

// if (loopCount > 25) {

// pulseWidth = pulseIn(2, HIGH, 20000);

// //Serial.println(pulseWidth);

// if(pulseWidth < 500) {

// v1 = 0;

// }

// else {

// v1 = map(pulseWidth, 500, 2000, -12, 12);

// }

// //Serial.println(pulseWidth);

// motor.move(v1);

// loopCount = 0;

// }

// user communication

motor.move(target_voltage);

command.run();

//loopCount++;

//endTime = millis();

//Serial.println(startTime-endTime);

}

}