Hello, I’m having trouble getting some low-resistance “quadcoptor” type motors to spin past ~4K RPM. The motors work wonderfully, efficiently, and silently up to about 2K RPM, then after that start to use ridiculous amounts of power, topping out at ~4KRPM and consuming ~100W!

commanded_target_voltage, speed(rad/s), power consumed

0.1 - 28, 0.6W

0.5 - 103, 1.7W

1.0 - 356, 32W

1.5 - 439, 96W

-The motors work past 20K rpm with a cheap commercial ESC, consuming around 35W at 20KRPM

-The AS5048A sensor can accurately read RPMs past ~20KRPM (I tested this by leaving simpleFOC running with the monitor whilest hooking the 3 power phases to an ESC and cranking it up to 20KRPM)

-I tried different modulation types, motor downsampleing and anything else I could think of… NOthing works.

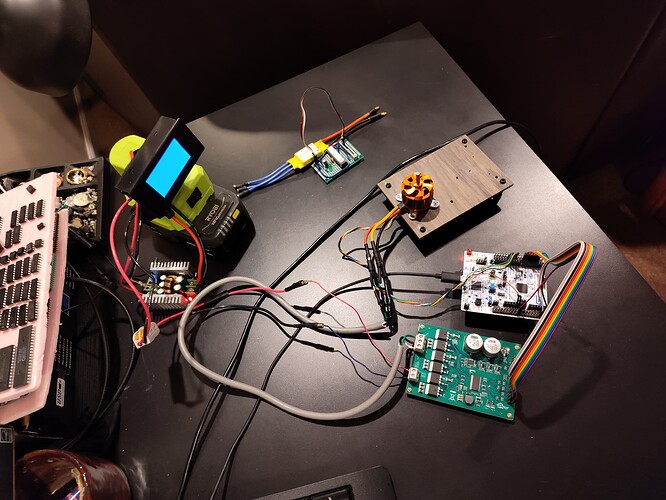

Motor: D3536, K=~2000, resistance=0.1Ohm, unloaded

Sensor: AS5048A

Driver: DRV8301 board, 3 PWM mode

Controller: NUCLEO G431RB

Algorithm: SimpleFOC, Torque mode, voltage feedback

/*

*/

#include <SimpleFOC.h>

#include "DRV8301.h"

MagneticSensorSPI sensor = MagneticSensorSPI(AS5147_SPI, 10); // MOSI=11, MISO=12, CSK=13.

DRV8301 gate_driver = DRV8301(3, 4, 5, 2, 6, 7); // MOSI, MISO, SCLK, CS, EN_GATE, FAULT

BLDCMotor motor = BLDCMotor(7); // 2208

BLDCDriver3PWM driver = BLDCDriver3PWM(PC0, PC1, PC2);

Commander command = Commander(Serial);

// void doMotor(char* cmd) { command.motor(&motor, cmd); }

void doTarget(char* cmd) {command.scalar(&motor.target, cmd);}

void doLimit(char* cmd) {command.scalar(&motor.voltage_limit, cmd);}

void doMotor(char* cmd) { command.motor(&motor, cmd); }

char msgbuf[256];

void setup() {

Serial.begin(921600); // WARNING: low value like 115200 cause distorted FOC

// for timer analysis

//SimpleFOCDebug::enable(&Serial);

//delay(5000);

Serial.printf("enter setup...\n");

sensor.init();

// link the motor to the sensor

motor.linkSensor(&sensor);

// driver config

// power supply voltage [V]

driver.voltage_power_supply = 18;

driver.voltage_limit = 4;

driver.init();

// configure the DRV8301

gate_driver.begin(PWM_INPUT_MODE_3PWM, 1); // no OCP

_delay(100);

int reg1, reg2, reg3, reg4, fault;

gate_driver.get_regs(®1, ®2, ®3, ®4);

fault = gate_driver.is_fault();

sprintf(msgbuf, "DRV8301: fault=%x, STATREG1=0x%.4x, STATREG2=0x%.4x, CTRLREG1=0x%.4x, CTRLREG2=0x%.4x", fault, reg1, reg2, reg3, reg4);

Serial.println(msgbuf);

// link driver

motor.linkDriver(&driver);

// link current sense and the driver

motor.voltage_sensor_align = 0.5;

//motor.controller = MotionControlType::torque;

motor.controller = MotionControlType::torque;

// default voltage_power_supply

motor.voltage_limit = 2;

motor.current_limit = 1000;

motor.velocity_limit = 100;

// contoller configuration based on the controll type

motor.PID_velocity.P = 0.1;

motor.PID_velocity.I = 1.0;

motor.PID_velocity.D = 0.0;

motor.PID_velocity.output_ramp = 1000.0;

motor.PID_velocity.limit = 1000.0;

motor.LPF_velocity.Tf = 0.1;

// angle loop controller

motor.P_angle.P = 30;

motor.motion_downsample = 10.0;

// set the inital target value

motor.target = 0;

// Serial.begin(115200); // WARNING: low value like 115200 cause distorted FOC

// comment out if not needed

motor.useMonitoring(Serial);

//motor.monitor_downsample = 0; // disable intially

motor.monitor_variables = _MON_TARGET | _MON_VOLT_Q | _MON_VOLT_D | _MON_CURR_Q | _MON_CURR_D | _MON_VEL | _MON_ANGLE; // monitor target velocity and angle

//motor.foc_modulation = SpaceVectorPWM;

// initialise motor

motor.init();

// align encoder and start FOC

motor.initFOC();

// subscribe motor to the commander

command.add('T', doTarget, "target"); // ssss space

command.add('L', doLimit, "voltage limit");

command.add('M',doMotor,"motor");

Serial.printf("setup complete...\n");

_delay(1000);

}

void loop() {

// iterative setting FOC phase voltage

motor.loopFOC();

// iterative function setting the outter loop target

motor.move();

// motor monitoring

motor.monitor();

// user communication

command.run();

}