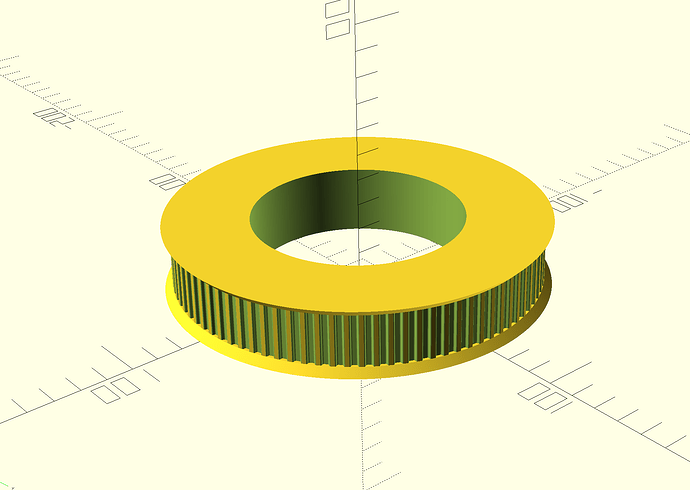

88 Teeth, paramedric

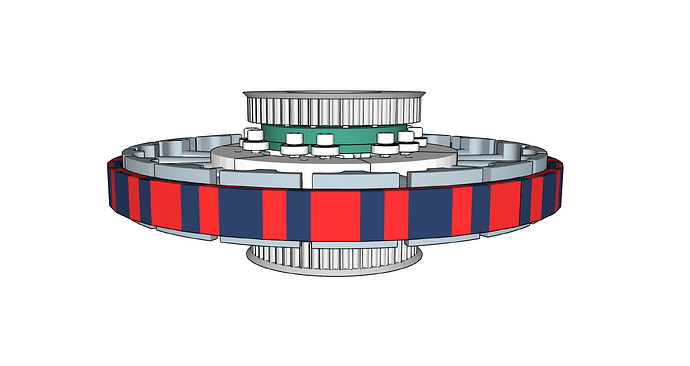

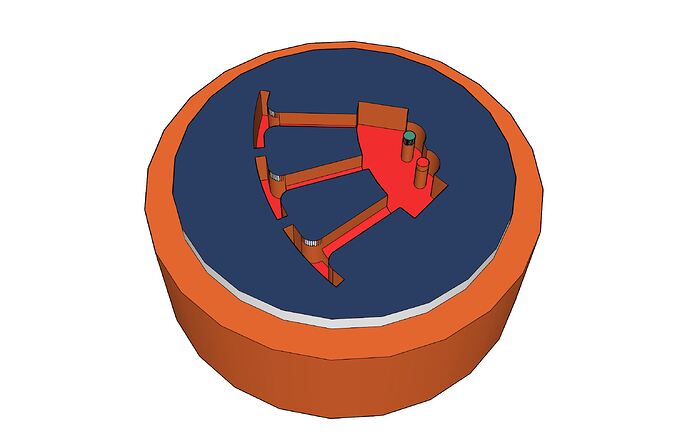

Dual pulley belt outrunner (20mm wide - HDT 8mm (or similar))

How can we equal out the forces on the pulley, as to not have the rotor twist by torque. Have the forces pull on either side.

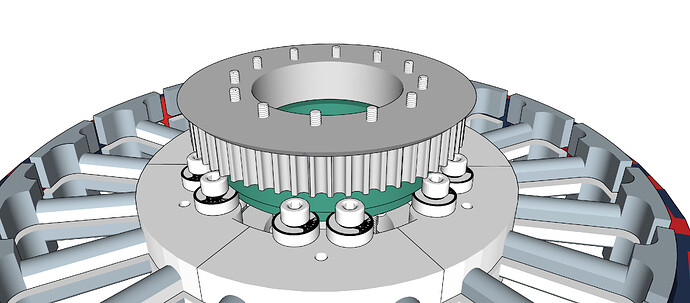

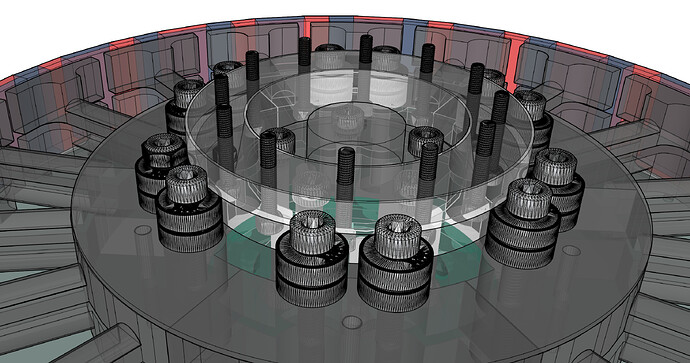

Changelog: Added DIY kevlar reinforced bearing, utilizing the M8 bolts as 22mm bearing anchors. (12 on either side). The drivetrain will put its torque on approx. 8 bearings at all time, plus the opposite side.. 22mm bearings (8mm bore) are easy to come by, since they are used for skateboards. The centrifugal forces will pull the magnets outwards (G´s), so the rotor will be applying invards pressure on the bearing, hence the kevlar reinforced edge on the bearings.

Center bore is 80mm, so ample room for attaching to frame on either side and routing cables/cooling. Bolts for rotor and pulley will be molded/casted into the master bearing, using high temp epoxy, combined with kevlar weave for structural integrity. Outer shell in contact with skate bearings can be printed using nilon. It might still be wise to use a machined mold or machined bearing with M5 thread.

Note: locknuts has to turn the right way around, or they might interfere with the master bearing. Alternatively a wider bearing (8mm bore) can be used. Alternatively a custom nut can be used.

Essentially, one can also print the pulleys with room/slits for kevlar reinforcement.

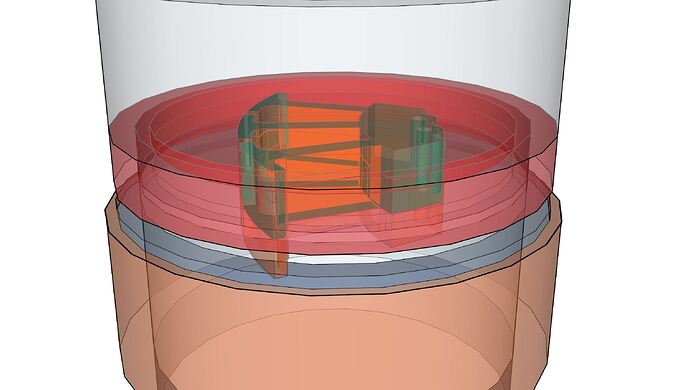

How compact can you make iron inside a large electromagnet? Large and hot elektromagnet I might add

The Høganes coated iron powder cures at 650 degrees C.

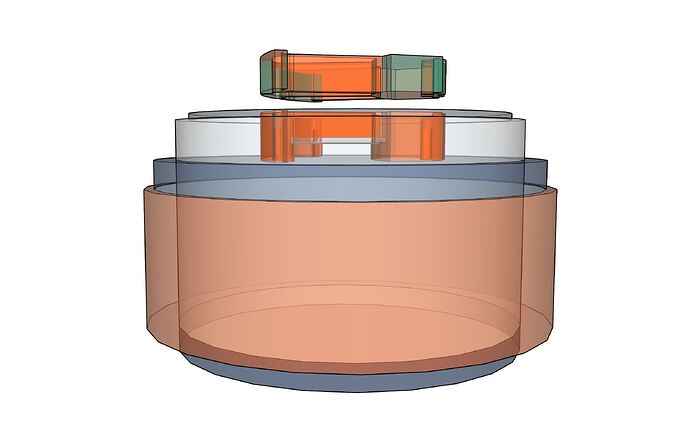

Edith: The mold/magnet does not neet to get hot. If the press is constructed with two magnetically opposite pulling/pushing forces, The electromagnetic force on the coated powder will create a green part for further processing in a furnace.

The closer the two poles get´s, the higher the force is applied.

So, the sides of the mold, should partly be stainless.

We need ejector rods, going all the way through

Remove mold cavity, rotate and eject ![]()

Solid iron core electromagnet. A.k.a sand casting pure iron

POM lip, this is harmony under pressure

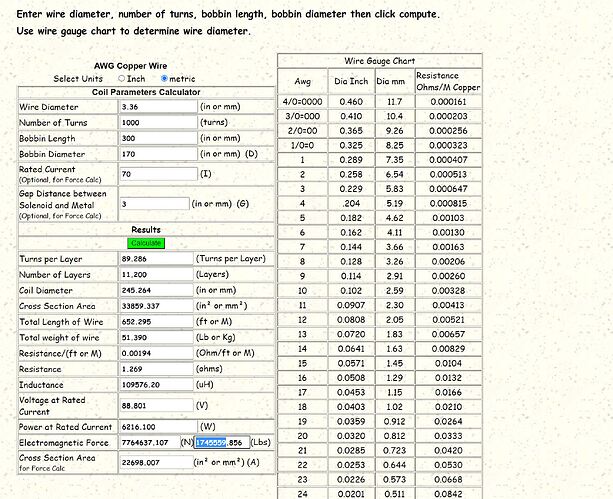

@runger how hot will this coil get @70 amp and what is the electromagnetic force between two opposite electro magnets ?

@Jason_Kirsons you think we should increase the voltage ?

What happens, if you compress the powder iron until you can not compress it any more, and then compress it further 3/5mm?

When will we react the green part?

@Owen_Williams; when stars collide

For somewhat smaller self-made motors, check out what this guy is doing: