Hi.

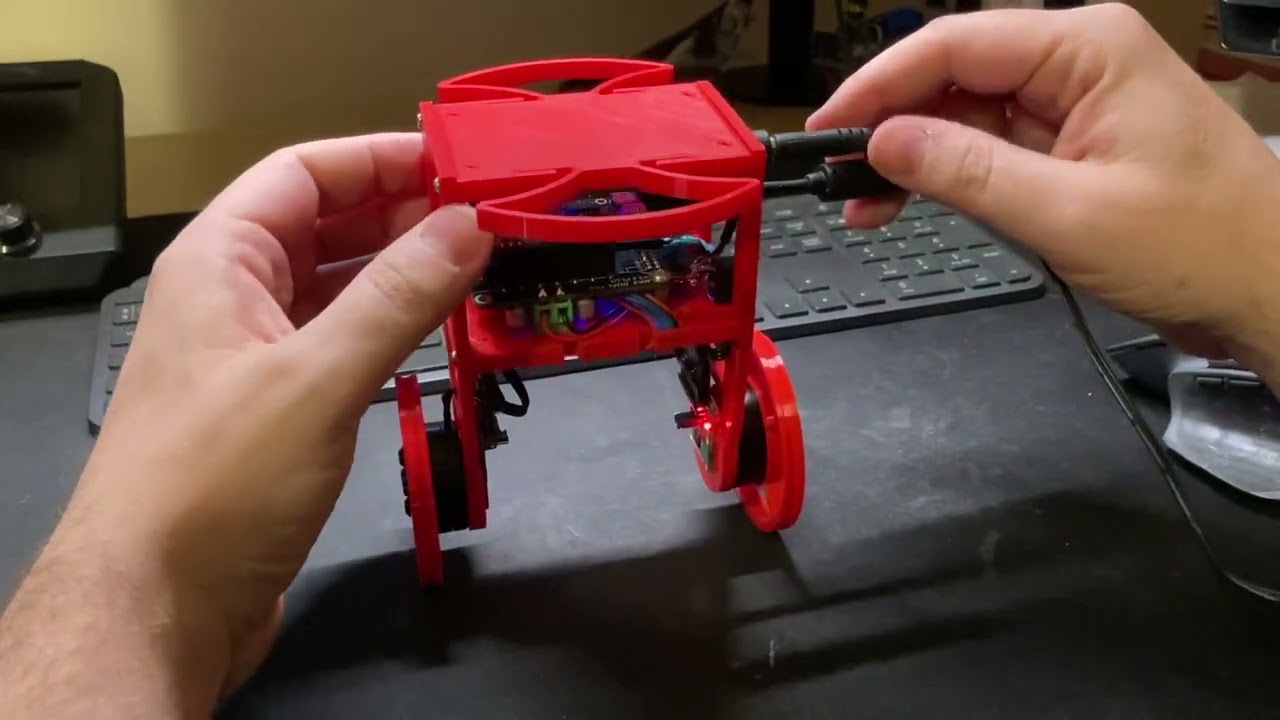

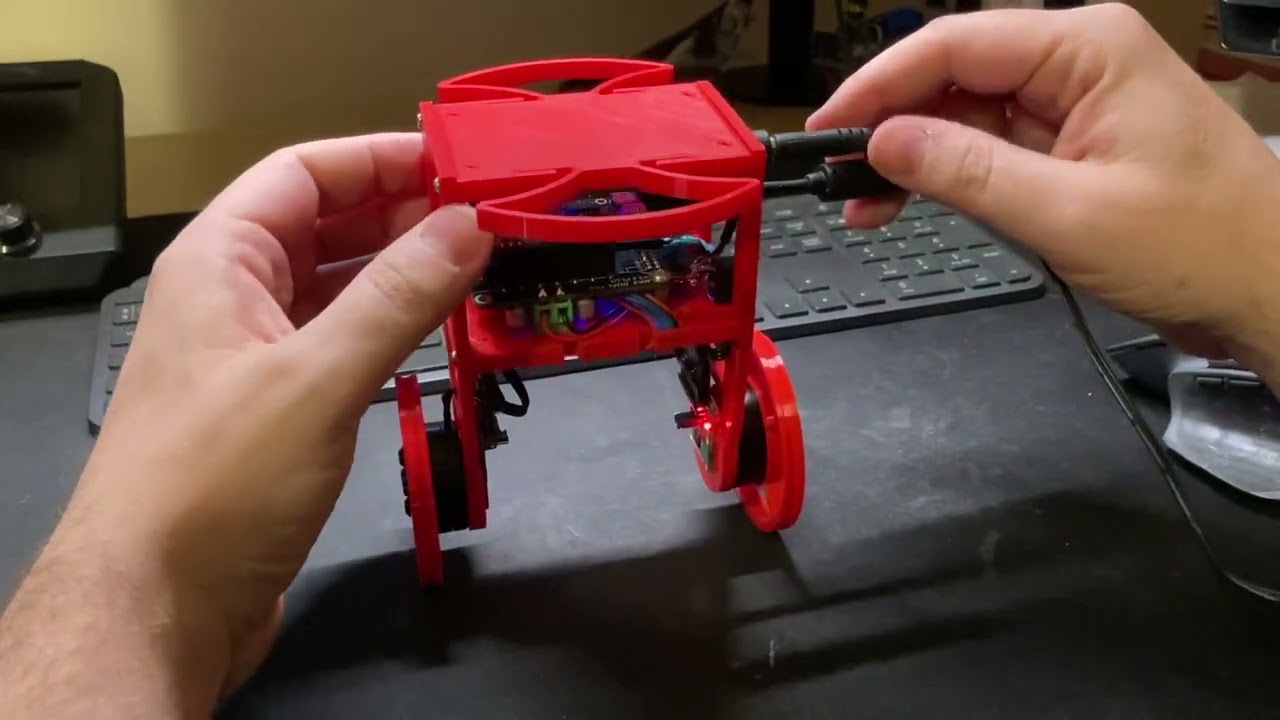

Today, the missing element finally arrived and I was able to return to the robot. I adjusted the Arduino-FOC-balancer code to fit my needs. Unfortunately, the robot, as shown in the video, did not work well. Maybe you have suggestions on what’s not working properly

#include <SimpleFOC.h>

#include "imu_helpers.h"

#include "BluetoothSerial.h"

BluetoothSerial bluetooth;

BLDCMotor motor1 = BLDCMotor(7);

BLDCDriver3PWM driver1 = BLDCDriver3PWM(32, 33, 25, 22);

MagneticSensorSPI encoder1 = MagneticSensorSPI(AS5147_SPI, 15); //- R

BLDCMotor motor2 = BLDCMotor(7);

BLDCDriver3PWM driver2 = BLDCDriver3PWM(26, 27, 14, 12);

MagneticSensorSPI encoder2 = MagneticSensorSPI(AS5147_SPI, 5); // - L

PIDController pid_stb{.P = 30, .I = 100, .D = 1, .ramp = 100000, .limit = 7};

PIDController pid_vel{.P = 0.01, .I = 0.03, .D = 0, .ramp = 10000, .limit = _PI / 10};

LowPassFilter lpf_pitch_cmd{.Tf = 0.07};

LowPassFilter lpf_throttle{.Tf = 0.5};

LowPassFilter lpf_steering{.Tf = 0.1};

float steering = 0;

float throttle = 0;

float max_throttle = 10; // 20 rad/s

float max_steering = 1; // 1 V

int state = 1; // 1 on / 0 off

Commander commander = Commander(Serial);

void cntStab(char *cmd) { commander.pid(&pid_stb, cmd); }

void cntMove(char *cmd) { commander.pid(&pid_vel, cmd); }

void lpfPitch(char *cmd) { commander.lpf(&lpf_pitch_cmd, cmd); }

void lpfSteering(char *cmd) { commander.lpf(&lpf_steering, cmd); }

void lpfThrottle(char *cmd) { commander.lpf(&lpf_throttle, cmd); }

void setup()

{

Serial.begin(250000);

_delay(1000);

if (!initIMU())

{

Serial.println(F("IMU connection problem... Disabling!"));

return;

}

_delay(1000);

encoder1.init();

encoder2.init();

motor1.linkSensor(&encoder1);

motor2.linkSensor(&encoder2);

driver1.voltage_power_supply = 4;

driver1.init();

motor1.linkDriver(&driver1);

driver2.voltage_power_supply = 4;

driver2.init();

motor2.linkDriver(&driver2);

motor1.controller = MotionControlType::torque;

motor2.controller = MotionControlType::torque;

motor1.useMonitoring(Serial);

motor2.useMonitoring(Serial);

motor1.init();

motor2.init();

motor1.initFOC();

motor2.initFOC();

commander.add('A', cntStab, "pid stab");

commander.add('B', cntMove, "pid vel");

commander.add('C', lpfThrottle, "lpf vel command");

commander.add('D', lpfPitch, "lpf throttle");

commander.add('E', lpfSteering, "lpf steering");

Serial.println(F("Balancing robot ready!"));

}

void loop()

{

motor1.loopFOC();

motor2.loopFOC();

motor1.move();

motor2.move();

if (!state)

{

motor1.target = 0;

motor2.target = 0;

}

else if (hasDataIMU())

{

float pitch = getPitchIMU();

float target_pitch = lpf_pitch_cmd(pid_vel((motor1.shaft_velocity + motor2.shaft_velocity) / 2 - lpf_throttle(throttle)));

float voltage_control = pid_stb(target_pitch - pitch);

float steering_adj = lpf_steering(steering);

motor1.target = voltage_control + steering_adj;

motor2.target = voltage_control - steering_adj;

}

commander.run();

handleBluetooth(bluetooth);

}

void handleBluetooth(Stream &bt_port)

{

int inByte;

if (bt_port.available() > 0)

{

while (bt_port.available())

{

inByte = bt_port.read();

}

inByte = inByte - 100;

if (inByte == 155)

{

steering = 0;

throttle = 0;

state = 1;

}

else if (inByte == 154)

{

steering = 0;

throttle = 0;

state = 0;

}

else if (inByte >= -100 && inByte <= 100)

{

throttle = max_throttle * ((float)inByte) / 100.0;

}

else if (inByte >= 110 && inByte <= 150)

{

steering = max_steering * ((float)(inByte - 130.0)) / 20.0;

}

else

{

steering = 0;

throttle = 0;

}

bt_port.flush();

}

}

serial port:

Initializing I2C devices...

Testing device connections...

MPU6050 connection successful

Initializing DMP...

>......

-2302.00000, -2333.00000, 1532.00000, 151.00000, 101.00000, 40.00000

Enabling DMP...

DMP ready! Waiting for first interrupt...

Adjusting DMP sensor fusion gain...

MOT: Monitor enabled!

MOT: Monitor enabled!

MOT: Init

MOT: Enable driver.

MOT: Init

MOT: Enable driver.

MOT: Align sensor.

MOT: sensor_direction==CW

MOT: PP check: fail - estimated pp: 18.06

MOT: Zero elec. angle: 1.86

MOT: No current sense.

MOT: Ready.

MOT: Align sensor.

MOT: sensor_direction==CCW

MOT: PP check: fail - estimated pp: 1.08

MOT: Zero elec. angle: 1.83

MOT: No current sense.

MOT: Ready.

Balancing robot ready!

[ 22552][E][Wire.cpp:513] requestFrom(): i2cRead returned Error 263

[ 39614][E][Wire.cpp:513] requestFrom(): i2cRead returned Error 263

[ 61501][E][Wire.cpp:513] requestFrom(): i2cRead returned Error 263

The error “i2cRead returned Error” is worrying me

I added i2c configuration to the imou _helpers file

int initIMU() {

Wire.begin(0, 4);

Wire.setClock(400000); // 400kHz I2C clock. Comment this line if having compilation difficulties

...

I use a 9V 800mA power supply, and I’m wondering if the power supply might be the problem.