Hello everyone.

This is my first post and I just have to say that I’m excited to be able to play around with this project, SimpleFOC is amazing!

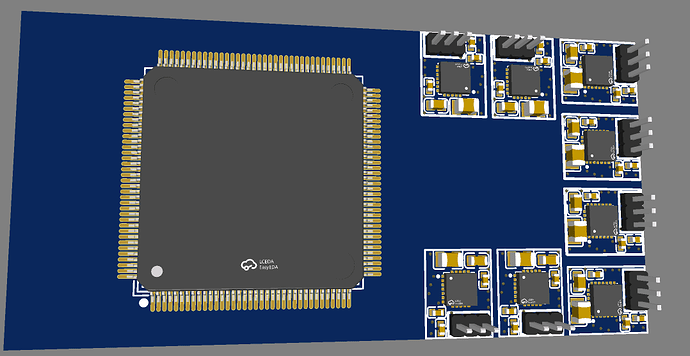

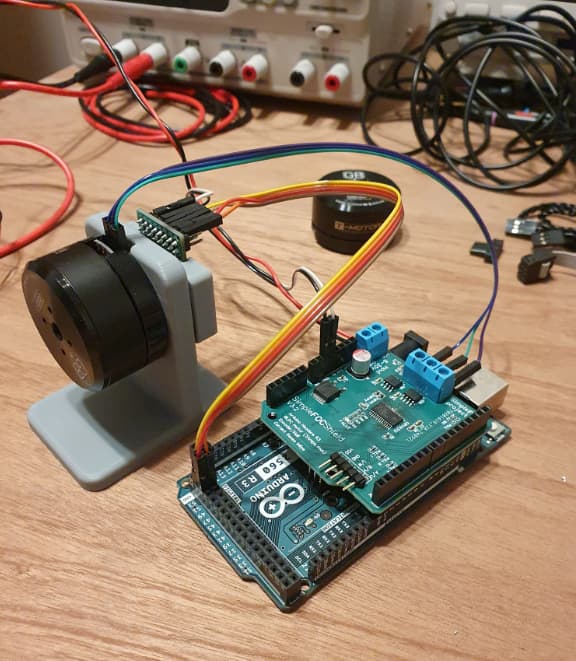

I’m pretty new to the system but I’ve managed to set up a basic test on my bench. I bought some GB36-1 gimble motors and got some PCBs made of the SimpleFOC shield v3. I’ve been out of coding for a while but I’m getting the hang of it.

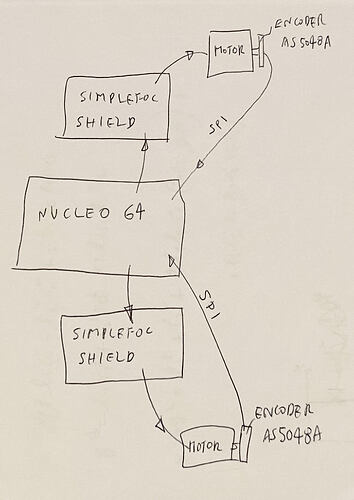

My goal is to have multiple motors running at the same time, say for a robot arm or something. I see that a microcontroller can run two motors at the same, and that more than that might be problematic due to the hardware not having enough timers to run the PWM for the drivers, if I understand correctly.

I’d be pretty happy with having one microcontroller per driver and another microcontroller acting as a coordinator/controller for the lot. What I am unsure of is what would be the best way to communicate between the coordinator and the driver controllers?

Would I be able to use SPI if there are spare SPI ports? What would I be able to get away with without upsetting the FOC instances?

I guess I am unsure of how much extra code I can put in, seems like the FOC code takes up a lot of the microcontrollers resources.