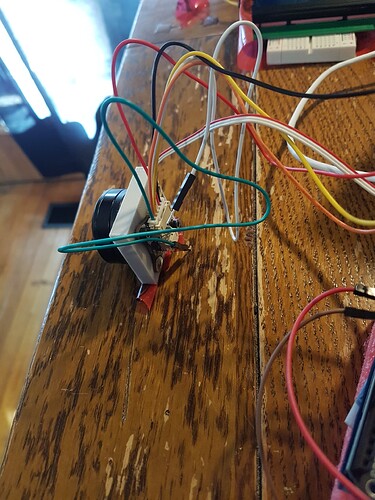

I am trying to get constant velocity mode working with. SimpleFOC arduino shield board with an AS5600 I2C encoder and magnet.

I’ve hit a wall because the page for the motor commander commands is 404, not found. The ? command that is supposed to list all commands doesn’t seem to work.

I tried the constant velocity example, modified it for the I2C sensor ok, and it initializes, but there appears to be an error in the example code, it says dotarget is not defined in this context, which is true. I have no idea what dotarget is supposed to be doing, I usually use micropython. I tried removing it and hard coding a constant velocity (100) into the code, but cannot get it moving. I’ll post the code in a second, I am on the wrong computer right now.

What I am after is smooth, quiet motion up to about 4000 rpm. I need to be able to reverse direction and have relatively good acceleration. This is just for a fan. I know simpleFOC may be overkill, but I was planning on using the lepton, which is similar in price to typical sensorless foc boards anyway, and I might need anti cogging. UPS lost the package so I am trying to get on with things with this arduino shield instead, hoping I can get the code working and verify the system can provide quiet, smooth operation at suitable speed and efficiency (can’t have the motor overheating).

I can tune the PID loop ok, I am familiar with that. I do not really need a PID and wouldn’t mind disabling that.

But I’ve hit a wall here, I need those commands. Also, do I need to use the system in velocity control mode for smooth high velocity motion?