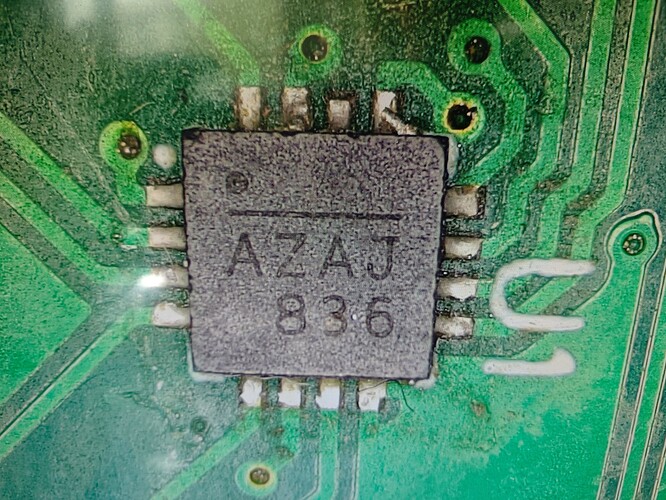

In SimpleFOC, I used two types of magnetic encoders. One has the marking “AVQJ,” but I’m not sure what model it is—it works perfectly at both low and high speeds. The other one is marked “AZAJ,” which should be the MA730. This encoder works fine at low speeds but has issues at high speeds. In voltage-controlled torque mode, when I stop the motor from rotating at high speed, the motor briefly spins in reverse before rotating forward again. It even starts oscillating, causing the motor to spin back and forth automatically.

I suspect that when the motor is forced to stop abruptly during high-speed rotation, the rapid deceleration causes incorrect encoder readings.