Hey everyone, I am still trying to build an open source energy recovery ventilator (openerv.org). I need quiet motors, with precise RPM control.

I can use the included open loop library example to control the motor’s rpm, as a demo. I got the wiring from this thread, there is none included in the example https://community.simplefoc.com/t/3-bldc-and-stepper-foc-driver-l298n/296/45

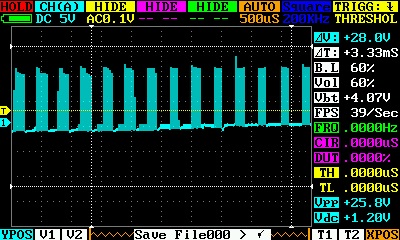

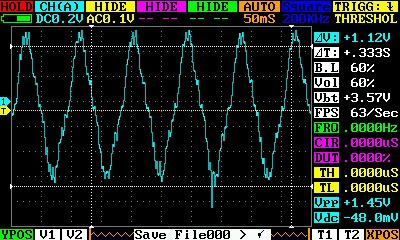

But as the video shows, it is very jerky. Any ideas on how I can get smooth motion? It is quiet, though. https://drive.google.com/file/d/1TM7Z1hcQRhO5YeksKZCLbeHRdPiJlpsH/view?usp=sharing

This is the code I used:

// Open loop motor control example

#include <SimpleFOC.h>

// BLDC motor & driver instance

// BLDCMotor motor = BLDCMotor(pole pair number);

BLDCMotor motor = BLDCMotor(11);

// BLDCDriver3PWM driver = BLDCDriver3PWM(pwmA, pwmB, pwmC, Enable(optional));

BLDCDriver3PWM driver = BLDCDriver3PWM(9, 10, 11);

// Stepper motor & driver instance

//StepperMotor motor = StepperMotor(50);

//StepperDriver4PWM driver = StepperDriver4PWM(9, 5, 10, 6, 8);

//target variable

float target_velocity = 0;

// instantiate the commander

Commander command = Commander(Serial);

void doTarget(char* cmd) { command.scalar(&target_velocity, cmd); }

void doLimit(char* cmd) { command.scalar(&motor.voltage_limit, cmd); }

void setup() {

pinMode(8,OUTPUT);

digitalWrite(8,LOW);

// driver config

// power supply voltage [V]

driver.voltage_power_supply = 12;

// limit the maximal dc voltage the driver can set

// as a protection measure for the low-resistance motors

// this value is fixed on startup

driver.voltage_limit = 6;

driver.init();

// link the motor and the driver

motor.linkDriver(&driver);

// limiting motor movements

// limit the voltage to be set to the motor

// start very low for high resistance motors

// currnet = resistance*voltage, so try to be well under 1Amp

motor.voltage_limit = 3; // [V]

// open loop control config

motor.controller = MotionControlType::velocity_openloop;

// init motor hardware

motor.init();

// add target command T

command.add('T', doTarget, "target velocity");

command.add('L', doLimit, "voltage limit");

Serial.begin(115200);

Serial.println("Motor ready!");

Serial.println("Set target velocity [rad/s]");

_delay(1000);

}

void loop() {

// open loop velocity movement

// using motor.voltage_limit and motor.velocity_limit

motor.move(target_velocity);

// user communication

command.run();

}