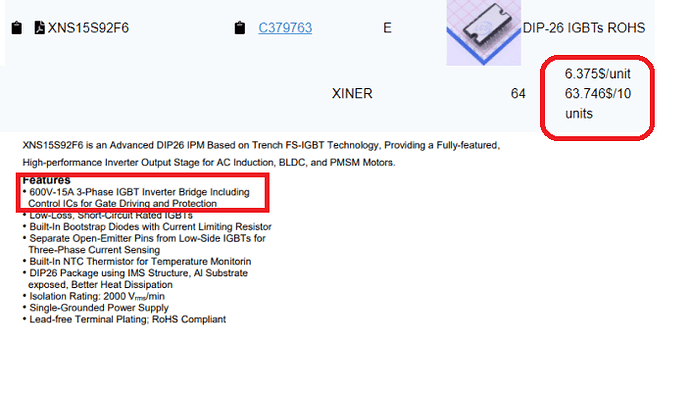

We need a board on amazon, ready to use, though, not a chip we can’t find, which requires a pcb or design to use. It may seem like stuff you can do with one hand tied behind your back, but hunting down a suitable chip, actually obtaining it at a reasonable price (including shipping), in a reasonable time frame, adding any support components, figuring out how to get it working in a logical way, maybe even making a pcb for it, is too large an undertaking for most people most of the time for most projects. I would probably encounter problems like finding out the timing characteristics of the chip are no good way too late in the project and have to do everything 3 times before I got anywhere. That’s why everyone is trending towards using the l298n units. When you hop on amazon or aliexpress, that’s all there is that can do the job. There are one or two other little mosfet based ones that may or may not work, but it’s not clear, given timing constraints, and truth table combinations and so on.

I believe a good tool set is one that makes problems more tractable. We should be making stepping stones upon which others can stand and reach further than we can. People have projects that are worthy and they want to do, but the commons isn’t ready to make it economically viable to do most of them. If we advance the lego kit that is available to people, then a lot of good stuff will come out of that.

A driver chip is only part of a driver, which is only part of a motion solution, which is only part of a larger assembly or equipment kit, which is only part of some technique that actually improves life, and then only usually a little bit. Each stage can’t be this complicated, we have to divide and conquer, I think. We have to respect how much work it is to get even a small improvement in life, and try to make things more practical at every stage.

My project, open erv, has 12 printed parts, 3 motors, an mcu, power supply, screws, regen media, bearings, 2 dual sensor boards, motor driver boards, fans and fan housing, connectors, wiring, all of which have to be sourced etc. and that’s a relatively simple project, compared to many I can think of I would like to undertake. It only gives you some fresh air and saves some energy, it doesn’t make you rich overnight. It can’t cost $1000. If every stage was so complicated, it would not be at all viable to develop it. It isn’t, really, it has become a hobby and labor of love, not a viable side hustle, to be honest.

When I was searching for a driver stage, it was just to test, just to check, how much noise was coming from the driver and how much was coming from the motor’s mechanics. A sub project of a sub project of a sub project of even the best, most worthy project I can undertake, is still not worth much. I can’t spend days sourcing parts and figuring out everything, wait a month for delivery etc., if you see what I mean.