Hi @runger bit of an update, I have got almost everything working. I can’t get the PWM function working.

void* pwm1params;

pwm1params = _configure1PWM(1000, A_PWM);

_writeDutyCycle1PWM(50, pwm1params);

The analog write is working, so currently using that.

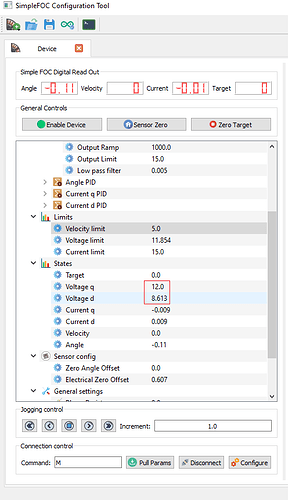

The other problem I have is when ever I disable the motor under load or in motion the PIDs keep calculating and give motor full voltage/current when I enable the motor again. Is there away to set all these to 0 and stop calculations while motor is disabled?

Here is the motor protection code for the B_G431B_ESC1 so far with braking and works well if anyone else is interested, it’s messy and unfinished, just add to your libs folder.

Header

#ifndef motorProtection

#define motorProtection

#include "Arduino.h"

#include <SimpleFOC.h>

class mpClass{

public:

//Declare all Functions

void begin();

void loop();

void reset();

float readVbus();

float readTemp();

void doMotorProtectCommand(char *command);

float mpPID(float SP, float PV, float P, float I, float D, float Min, float Max, float Cycle);

void linkMotor(BLDCMotor*);

void linkEncoder(Encoder*);

void linkBLDCDriver6PWM(BLDCDriver6PWM*);

void linkLowsideCurrentSense(LowsideCurrentSense*);

float brake_P = 1;

float brake_I = 10;

float brake_D = 0;

float brake_Min = 0;

float brake_Max = 250;

float brake_Cycle = 0;

unsigned long update = 1000;

float brakeEngageOffset = 0.25;

float brakeEngageMaxOffset = 2.0;

float brakeEngageMaxDisableOffset = 3.0;

float brakeCutOffPeriod = 250;

float temperature;

float tempCutOff = 60.0;

float tempDelayPeriod = 500;

float stallDelayPeriod = 100;

float stallCurrentOffset = 0.1;

float stallVoltageOffset = 0.1;

float overCurrentOffset = 0.05;

float overVoltageOffset = 0.05;

float overCVDelayPeriod = 100;

int mVelCnt = 6;

float mVelOffset = 1;

float mVelPeriod = 250;

int mAngleCnt = 8;

float mAngleOffset = 0.1;

float mAnglePeriod = 500;

int mCurrentQcnt = 10;

float mCurrentQoffset = 1.5;

float mCurrentQperiod = 100;

int mCurrentDcnt = 10;

float mCurrentDoffset = 1.5;

float mCurrentDperiod = 100;

int mVoltageQcnt = 10;

float mVoltageQoffset = 1.5;

float mVoltageQperiod = 200;

int mVoltageDcnt = 10;

float mVoltageDoffset = 1.5;

float mVoltageDperiod = 200;

class internal{

public:

bool oscillating(float input, int cnt, float offset, float period);

float input;

int cnt;

float offset;

float period;

private:

bool out;

bool outNew;

bool init;

float oldValue;

int cntUp;

int cntDown;

bool dirUp;

bool dirDown;

bool osOscillating;

};

private:

float VBus;

float pwmPID;

float pwmDuty;

bool motorVoscillation;

bool motorAoscillation;

bool currentQoscillation;

bool currentDoscillation;

bool voltageQoscillation;

bool voltageDoscillation;

byte brakeMode;

#define brakeOff 1

#define brakeEngage 2

#define brakeEngageMax 3

#define brakeEngageMaxDisableMotor 4

BLDCMotor* motor;

Encoder* encoder;

BLDCDriver6PWM* driver;

LowsideCurrentSense* currentSense;

};

#endif

#include "motorProtection.h"

//Motor Protections will disable motor

//Will self reset fault condition if in safe condition and allow you to enable motor again

//Motor Protection functions Include:

//Bus Overvoltage Braking

//Temperature Protection

//Stall Protection

//Over Current / Voltage Protection

//Oscillation Protection

//Link all objects from main ( not all are needed but here for future )

void mpClass::linkMotor(BLDCMotor *motorReference){

motor = motorReference;

}

void mpClass::linkEncoder(Encoder *encoderReference){

encoder = encoderReference;

}

void mpClass::linkBLDCDriver6PWM(BLDCDriver6PWM *driverReference){

driver = driverReference;

}

void mpClass::linkLowsideCurrentSense(LowsideCurrentSense *currentSenseReference){

currentSense = currentSenseReference;

}

//Create instance for function call per object

mpClass::internal VClass;

mpClass::internal AClass;

mpClass::internal CQClass;

mpClass::internal CDClass;

mpClass::internal VQClass;

mpClass::internal VDClass;

void mpClass::doMotorProtectCommand(char *mpCommand){

switch (mpCommand[0]){

case 'R':

reset();

break;

case 'D':

motor->disable();

break;

case 'E':

motor->enable();

break;

case 'V':

Serial.printf("Bus Voltage Reading: %f \n", readVbus());

break;

case 'T':

Serial.printf("G431 Temperature: %f \n", readTemp());

break;

}

}

void mpClass::reset(){

//Reset/Restart Driver reinitialize driver and motor calibration

//TODO

}

bool mpClass::internal::oscillating(float input, int cnt, float offset, float period){

if (!init){

oldValue = fabs(input);

init = true;

}

if (fabs(input) > (oldValue + offset)){

dirUp = true;

dirDown = false;

}

else if (fabs(input) < (oldValue - offset)){

dirUp = false;

dirDown = true;

}

else {

dirUp = false;

dirDown = false;

}

oldValue = fabs(input);

if (dirUp)cntUp++;

else if (dirDown)cntDown++;

if (cntUp >= cnt && cntDown >= cnt){

if(!osOscillating){

out = true;

osOscillating = true;

}

else{

out = false;

}

}

else{

out = false;

}

static long delayOscillating = millis();

if (millis() - delayOscillating > period) {

cntUp = 0;

cntDown = 0;

out = false;

osOscillating = false;

delayOscillating = millis();

}

return out;

}

//Important call from class and assign object for static variables!

//Must always be called in loop!

float mpClass::mpPID(float SP, float PV, float pGain, float iGain, float dGain, float Min, float Max, float Cycle){

static unsigned long previousMicros;

static float pErr;

static float Err;

static float P;

static float I;

static float D;

static float Out;

if (micros() - previousMicros >= Cycle) {

previousMicros = micros();

Err = (SP - PV);

P = (pGain * Err);

I = (I+(Err*iGain*Cycle));

if(I > Max) I = Max; //Prevent Integral windup

else if(I < Min) I = Min;

D = (dGain*(pErr-Err)/Cycle);

pErr = Err;

Out = (P + I + D);

if(Out < Min) Out = Min; //Clamp output to the limits

else if(Out > Max) Out = Max;

}

return Out;

}

float mpClass::readVbus(){

float vbus = _readADCVoltageLowSide(A_VBUS, currentSense->params);

vbus = vbus * 10.7711;

return vbus;

}

float mpClass::readTemp(){

float tADC = _readADCVoltageLowSide(A_TEMPERATURE, currentSense->params);

static const float ResistorBalance = 4700.0;

static const float Beta = 3425.0F;

static const float RoomTempI = 1.0F/298.15F; //[K]

static const float Rt = ResistorBalance * ((3.3F / tADC)-1);

static const float R25 = 10000.0F;

float temp = 1.0F/((log(Rt/R25)/Beta)+RoomTempI);

temp = temp - 273.15;

return temp;

}

void mpClass::begin() {

driver->voltage_power_supply = readVbus();

motor->voltage_limit = driver->voltage_power_supply;

}

void mpClass::loop(){

static unsigned long previousMicros;

if (micros() - previousMicros >= update) {

previousMicros = micros();

//Read Bus voltage

VBus = readVbus();

//Call PID

pwmPID = mpPID(driver->voltage_power_supply, VBus, brake_P, brake_I, brake_D, brake_Min, brake_Max, brake_Cycle);

//Disable Motor If bus voltage to high, otherwise let's dump it through brake resistor

static bool osBrake;

if (VBus > (driver->voltage_power_supply + brakeEngageMaxDisableOffset) && (motor->shaft_velocity > 0.01)) {

static long delay = millis();

if (millis() - delay > brakeCutOffPeriod && !osBrake) {

brakeMode = brakeEngageMaxDisableMotor;

SIMPLEFOC_DEBUG("Bus Voltage to high, Disable Motor: ", VBus);

delay = millis();

osBrake = true;

}

}

else if (VBus > (driver->voltage_power_supply + brakeEngageMaxOffset) && (motor->shaft_velocity > 0.01)) {

brakeMode = brakeEngageMax;

}

else if (VBus > (driver->voltage_power_supply + brakeEngageOffset) && (motor->shaft_velocity > 0.01)) {

brakeMode = brakeEngage;

}

else if (VBus < (driver->voltage_power_supply + 0.1)) {

brakeMode = brakeOff;

osBrake = false;

}

switch(brakeMode)

{

case brakeOff:

pwmDuty = 0;

break;

case brakeEngage:

pwmDuty = pwmPID;

break;

case brakeEngageMax:

pwmDuty = 245;

break;

case brakeEngageMaxDisableMotor:

pwmDuty = 250;

motor->disable();

break;

}

analogWrite(A_PWM, pwmDuty);

//TODO get the _writeDutyCycle1PWM working

//Should not be using analogWrite

//void* pwm1params;

//pwm1params = _configure1PWM(1000, A_PWM);

//_writeDutyCycle1PWM(0.5, pwm1params);

static bool osTemp;

temperature = readTemp();

if (temperature > tempCutOff){

static long delay = millis();

if (millis() - delay > tempDelayPeriod && !osTemp) {

motor->disable();

SIMPLEFOC_DEBUG("Driver Over Temperature, Disable Motor: ", temperature);

delay = millis();

osTemp = true;

}

}

else{

osTemp = false;

}

//Detect if motor has stalled and shutoff controller

static bool osStall;

if (fabs(motor->current.q) >= (motor->current_limit - stallCurrentOffset)) {

if (fabs(motor->shaft_velocity) < 0.01){

static long delay = millis();

if (millis() - delay > stallDelayPeriod && !osStall) {

SIMPLEFOC_DEBUG("Motor Stalled Current, Disable Motor: ", motor->current.q);

motor->disable();

delay = millis();

osStall = true;

}

}

}

else if (fabs(motor->voltage.q) >= (motor->voltage_limit - stallVoltageOffset)) {

if (fabs(motor->shaft_velocity) < 0.01){

static long delay = millis();

if (millis() - delay > stallDelayPeriod && !osStall) {

SIMPLEFOC_DEBUG("Motor Stalled Voltage, Disable Motor: ", motor->voltage.q);

motor->disable();

delay = millis();

osStall = true;

}

}

}

else{

osStall = false;

}

//Over Current and Over Voltage Protection

static bool osOverCV;

if ((fabs(motor->current.q) >= (motor->current_limit + overCurrentOffset))){

static long delay = millis();

if (millis() - delay > overCVDelayPeriod && !osOverCV) {

SIMPLEFOC_DEBUG("Motor Over Current, Disable Motor: ", motor->current.q);

motor->disable();

delay = millis();

osOverCV = true;

}

}

else if (fabs(motor->voltage.q) >= (motor->voltage_limit + overVoltageOffset)){

static long delay = millis();

if (millis() - delay > overCVDelayPeriod && !osOverCV) {

SIMPLEFOC_DEBUG("Motor Over Voltage, Disable Motor: ", motor->voltage.q);

motor->disable();

delay = millis();

osOverCV = true;

}

}

else{

osOverCV = false;

}

//Detect if Motor is in an uncontrollable state ie oscillating

motorVoscillation = VClass.oscillating(VClass.input = motor->shaft_velocity, VClass.cnt = mVelCnt, VClass.offset = mVelOffset, VClass.period = mVelPeriod);

motorAoscillation = AClass.oscillating(AClass.input = motor->shaft_angle, AClass.cnt = mAngleCnt, AClass.offset = mAngleOffset, AClass.period = mAnglePeriod);

currentQoscillation = CQClass.oscillating(CQClass.input = motor->current.q, CQClass.cnt = mCurrentQcnt, CQClass.offset = mCurrentQoffset, CQClass.period = mCurrentQperiod);

currentDoscillation = CDClass.oscillating(CDClass.input = motor->current.d, CDClass.cnt = mCurrentDcnt, CDClass.offset = mCurrentDoffset, CDClass.period = mCurrentDperiod);

voltageQoscillation = VQClass.oscillating(VQClass.input = motor->voltage.q, VQClass.cnt = mVoltageQcnt, VQClass.offset = mVoltageQoffset, VQClass.period = mVoltageQperiod);

voltageDoscillation = VDClass.oscillating(VDClass.input = motor->voltage.d, VDClass.cnt = mVoltageDcnt, VDClass.offset = mVoltageDoffset, VDClass.period = mVoltageDperiod);

if (motorVoscillation ||

motorAoscillation ||

currentQoscillation ||

currentDoscillation ||

voltageQoscillation ||

voltageDoscillation){

SIMPLEFOC_DEBUG("Motor Oscillating, Disable Motor");

motor->disable();

}

if (motorVoscillation) SIMPLEFOC_DEBUG("Motor Shaft Velocity Oscillating");

else if (motorAoscillation) SIMPLEFOC_DEBUG("Motor Shaft Angle Oscillating", motorAoscillation);

else if (currentQoscillation) SIMPLEFOC_DEBUG("Motor current Q Oscillating");

else if (currentDoscillation) SIMPLEFOC_DEBUG("Motor current D Oscillating");

else if (voltageQoscillation) SIMPLEFOC_DEBUG("Motor voltage Q Oscillating");

else if (voltageDoscillation) SIMPLEFOC_DEBUG("Motor voltage D Oscillating");

}

}

How to use: Add these your main file

//Motor Protection Instance

mpClass mProtection;

void doProtection(char *cmd){

mProtection.doMotorProtectCommand(cmd);

}

//ADD to your Setup/Begin

pinMode(A_PWM, OUTPUT);

//Enable SimpleFOC Debugging

SimpleFOCDebug::enable(&Serial);

// use monitoring with serial

Serial.begin(115200);

//Call at end of your setup!

//Motor Protection Settings

//Link all objects for motor protection class

mProtection.linkMotor(&motor);

mProtection.linkEncoder(&encoder);

mProtection.linkBLDCDriver6PWM(&driver);

mProtection.linkLowsideCurrentSense(¤tSense);

//Protection update rate in microseconds

mProtection.update = 250;

//Brake PID Paremeters

mProtection.brake_P = 10;

mProtection.brake_I = 100;

mProtection.brake_D = 0;

mProtection.brake_Min = 0;

mProtection.brake_Max = 250;

mProtection.brake_Cycle = 0;

//Brake Trigger (driver power supply + Offset amount above vbus)

mProtection.brakeEngageOffset = 0.25;

mProtection.brakeEngageOffset = 2.0;

mProtection.brakeEngageMaxDisableOffset = 3.0;

mProtection.brakeCutOffPeriod = 200;

//Temperature Settings

mProtection.tempCutOff = 60.0;

mProtection.tempDelayPeriod = 500;

//Stall Detection

mProtection.stallDelayPeriod = 100;

mProtection.stallCurrentOffset = 0.1;

mProtection.stallVoltageOffset = 0.1;

//Over Current/Voltage Protection

mProtection.overCurrentOffset = 0.05;

mProtection.overVoltageOffset = 0.05;

mProtection.overCVDelayPeriod = 100;

//Oscillating Detection

//Shaft Velocity

mProtection.mVelCnt = 6;

mProtection.mVelOffset = 1;

mProtection.mVelPeriod = 250;

//Shaft Angle

mProtection.mAngleCnt = 8;

mProtection.mAngleOffset = 0.1;

mProtection.mAnglePeriod = 250;

//Current Q

mProtection.mCurrentQcnt = 10;

mProtection.mCurrentQoffset = 1.5;

mProtection.mCurrentQperiod = 250;

//Current D

mProtection.mCurrentDcnt = 10;

mProtection.mCurrentDoffset = 1.5;

mProtection.mCurrentDperiod = 250;

//Voltage Q

mProtection.mVoltageQcnt = 10;

mProtection.mVoltageQoffset = 1.5;

mProtection.mVoltageQperiod = 250;

//Voltage D

mProtection.mVoltageDcnt = 10;

mProtection.mVoltageDoffset = 1.5;

mProtection.mVoltageDperiod = 250;

//Add Cammand for Motor Protection

command.add('P', doProtection, (char*)"Motor Protection");

//Call Motor Protection Setup

_delay(500);

mProtection.begin();

//Run this in the loop after motor.move

//Call Motor Protection Loop

mProtection.loop();

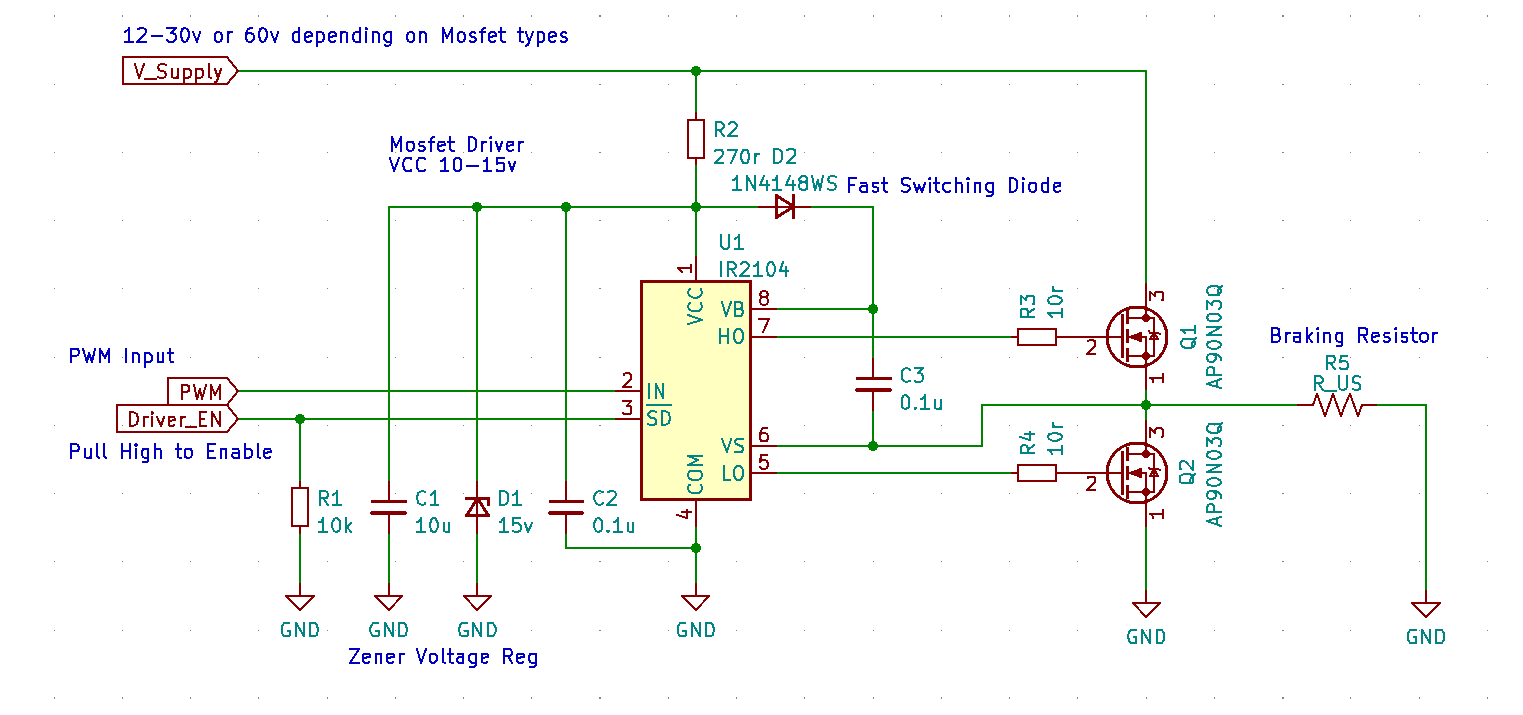

Here is the braking circuit I am using with the B_G431B_ESC1

Hopefully it helps others and is a good start, I will add to my github when I have everything working correctly