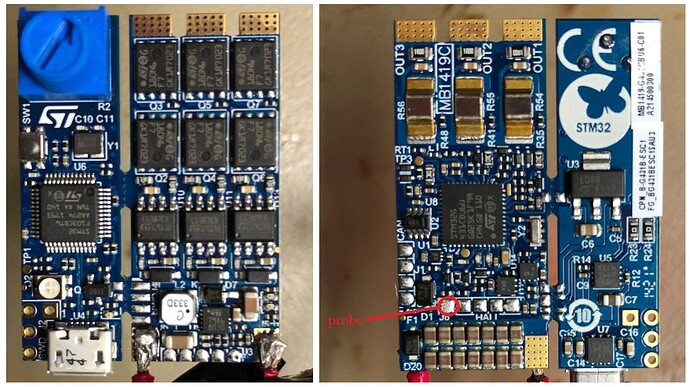

Thanks everyone for your help! I show you the tests I have done. I am using the arduino ide and to install B-G431B-ESC1 board I used the instructions of @ultra.robotics in beginner-guide-i2c-guide.

First of all, I ran the code related to open loop velocity control:

#include <SimpleFOC.h>

BLDCMotor motor = BLDCMotor(11);

BLDCDriver6PWM driver = BLDCDriver6PWM(PHASE_UH,PHASE_UL,PHASE_VH, PHASE_VL,PHASE_WH, PHASE_WL);

HallSensor sensor = HallSensor(HALL1,HALL2,HALL3,11);

void doA(){sensor.handleA();}

void doB(){sensor.handleB();}

void doC(){sensor.handleC();}

float target = 1.00; //[rad/s]

void serialLoop(){

static String received_chars;

while(Serial.available()){

char inChar = (char) Serial.read();

received_chars += inChar;

if(inChar == '\n'){

target = received_chars.toFloat();

Serial.print("Target = "); Serial.println(target);

received_chars = "";

}

}

}

void setup() {

Serial.begin(115200);

delay(1000);

sensor.init();

sensor.enableInterrupts(doA,doB,doC);

driver.voltage_power_supply = 12.0;

driver.init();

motor.linkDriver(&driver);

motor.voltage_limit = 1; //[V]

motor.velocity_limit = 20; //[rad/s]

motor.controller = MotionControlType::velocity_openloop;

motor.init();

}

void loop() {

serialLoop();

motor.move(target);

Serial.print(sensor.getAngle());

Serial.print("\t");

Serial.println(sensor.getVelocity());

}

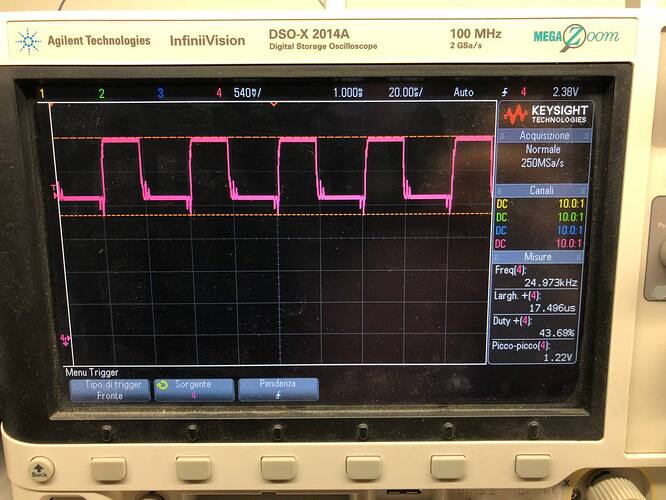

Attaching the oscilloscope probe to the HALL 1 pin I detected a PWM signal with a frequency of 25 kHz, with a variable duty cycle and with a signal amplitude of 2.2 Vpp:

I noticed that the PWM signal on pin HALL 1 is synchronized with the output signal related to phase 2 of the motor (green signal). Maybe this could be useful to find a possible bridge (hardware or software).

I also noticed that changing the value of the variable

motor.voltage_limit changes the range of variation of the duty cycle. For example by setting the variable voltage_limit = 1 the duty cycle range is 42-57%.I replaced the existing 10K pull up resistor with a 2.2K resistor and I obtained a decrease in the amplitude of the pwm signal on pin HALL1. This made it possible to avoid the increase of the number of false interrupts but did not actually solve the problem.