Hello everyone,

My objective is to build the world’s most springy, smooth, and compact gimbal BLDC motor (direct-drive)–driven robot arm using SimpleFOC, and this post marks my starting point. I have chosen the T-Motor GB series motors for this project.

I would like to share my current results and gather any meaningful advice you are willing to offer on how I can improve my SimpleFOC implementation for gimbal BLDC motors, specifically for position and velocity control.

I am also interested in learning about any proven, reliable BLDC drivers (up to 24 V and with built-in current sensing) that you use frequently and would recommend. My design philosophy would be to use a MCU and a driver along with all the bits on each motor hooked to a central MCU via SPI/UART to interface with my ROS2 PC with a USB A cable.

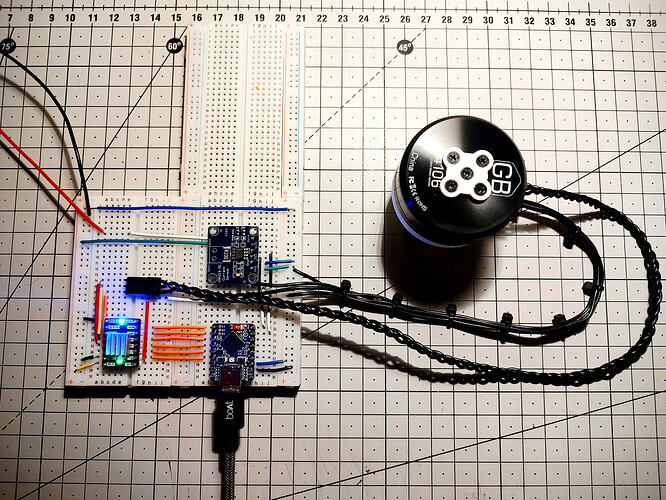

At the moment, I am working with the following hardware:

-

T-Motor GB4106

-

TMC6300 (three-phase driver)

-

Osram AS5600 (encoder)

-

ESP32-S3 Zero (a.k.a. the mini version)

-

INA219 (current sensor)

I havent decided on what electronics I would go with, again I will start with the best Motor driver and discover the other stuff on the way.

At the moment here are my results.

Here is the code (Below) I have developed based on the tutorials. It is functional and has been thoroughly tested. Below, you will also find several PID charts that I generated using a Python script. The methodology was to move the motor from Position A to Position B, capture the encoder data, and plot it on a graph. This allowed me to tune the PID parameters to achieve the smoothest possible motion.

I would appreciate any feedback on the PID graphs as well, particularly suggestions on how they could be further improved.

The command parameters used are:

- Target angle

- Velocity P

- Velocity I

- Velocity D

- Velocity LPF

- Angle P

- Voltage limit

#include <SimpleFOC.h>

#include <Wire.h>

// ---------------- Pins ----------------

const int phU_h = 11;

const int phU_l = 12;

const int phV_h = 9;

const int phV_l = 10;

const int phW_h = 7;

const int phW_l = 8;

// ---------------- Motor ----------------

// 12N14P motor → 7 pole pairs

BLDCMotor motor = BLDCMotor(7);

// ---------------- Driver ----------------

// TMC6300 → 6PWM

BLDCDriver6PWM driver = BLDCDriver6PWM(

phU_h, phU_l,

phV_h, phV_l,

phW_h, phW_l

);

// ---------------- Sensor ----------------

// AS5600 via I2C

MagneticSensorI2C sensor = MagneticSensorI2C(AS5600_I2C);

// ---------------- Commander ----------------

Commander command = Commander(Serial);

// -------- Commander callbacks --------

// Angle target (radians)

void doAngle(char* cmd) {

command.scalar(&motor.target, cmd);

}

// Velocity PID tuning (still used internally!)

void doVP(char* cmd) { command.scalar(&motor.PID_velocity.P, cmd); }

void doVI(char* cmd) { command.scalar(&motor.PID_velocity.I, cmd); }

void doVD(char* cmd) { command.scalar(&motor.PID_velocity.D, cmd); }

void doVLPF(char* cmd) { command.scalar(&motor.LPF_velocity.Tf, cmd); }

// Angle PID tuning

void doAP(char* cmd) {

command.scalar(&motor.P_angle.P, cmd);

}

// Voltage limit

void doVlim(char* cmd) {

command.scalar(&motor.voltage_limit, cmd);

}

void setup() {

Serial.begin(115200);

delay(1000);

// ---------------- I2C ----------------

Wire.begin(6, 5); // SDA, SCL

// ---------------- Sensor ----------------

sensor.init();

motor.linkSensor(&sensor);

// ---------------- Driver ----------------

driver.voltage_power_supply = 10.4;

driver.init();

motor.linkDriver(&driver);

// ---------------- Control mode ----------------

motor.controller = MotionControlType::angle;

// ---------------- Angle PID ----------------

motor.P_angle.P = 25.0; // start here (typical range 5–20)

// ---------------- Velocity PID (inner loop) ----------------

motor.PID_velocity.P = 0.5;

motor.PID_velocity.I = 0.1;

motor.PID_velocity.D = 0.001;

motor.LPF_velocity.Tf = 0.02;

motor.PID_velocity.output_ramp = 300;

// ---------------- Limits ----------------

motor.voltage_limit = 10.4; // VERY important in angle mode

//motor.velocity_limit = 20.0; // limits snap speed

// ---------------- Monitoring ----------------

motor.useMonitoring(Serial);

// ---------------- Init ----------------

motor.init();

motor.initFOC();

// ---------------- Commander ----------------

command.add('A', doAngle, "Target angle [rad]");

command.add('P', doVP, "Velocity P");

command.add('I', doVI, "Velocity I");

command.add('D', doVD, "Velocity D");

command.add('L', doVLPF, "Velocity LPF");

command.add('Q', doAP, "Angle P");

command.add('V', doVlim, "Voltage limit");

Serial.println("=================================");

Serial.println("Closed-loop ANGLE FOC READY");

Serial.println("Commands:");

Serial.println(" A <rad> - target angle");

Serial.println(" Q <val> - angle P");

Serial.println(" P/I/D/L - velocity PID");

Serial.println(" V <volt> - voltage limit");

Serial.println("=================================");

delay(1000);

}

void loop() {

// -------- FOC loop --------

motor.loopFOC();

// -------- Angle control --------

motor.move();

// Print velocity (optional, for debugging)

Serial.println(sensor.getAngle(), 6);

// -------- Commander --------

command.run();

}

PID Graphs results: This was captured Raw encoder values converted to radians vs time stamps. Here’s a video to demostrate the “Return to Position“.

Link to the Graphs - Google Drive

Heres the initial setup.

Have a nice day,

~Roland