You are missing all decoupling capacitors, and some more things that are recommend for STM32F1303C8T6.

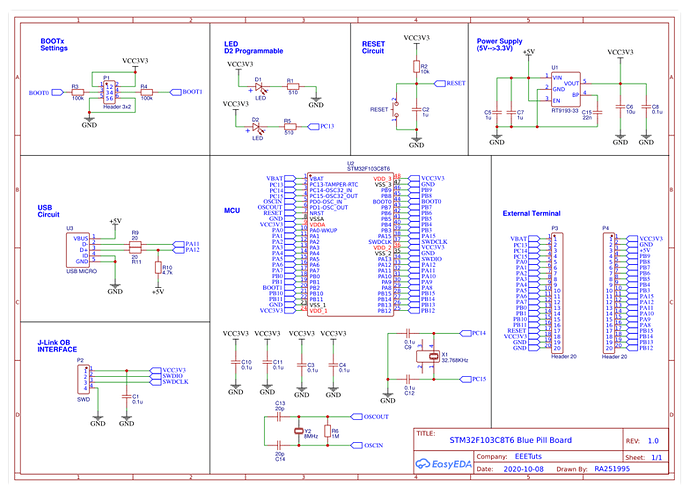

You can read Getting started with STM32F10xxx hardware development that explains what the MCU need. You can also look others designs to see what others do like this one Blue pill schematic

You can watch some videos on this channel that explains how to design and power boards with SMT32 KiCad STM32 Hardware Design - An Overview in 20 Minutes