Because I didn’t know about the mosquito :(. That is the only reason. I looked at the recommended hardware, and it wasn’t there IIRC. I also thought that there were issues with 3 pin pwm, however I think I was probably wrong about that.

Update: I hypothesized that during the dead period when neither mosfet is conducting, the half h-bridges cannot allow any current to pass in either direction. This is a deviation from the ideal of the 3 phase ac current situation. I thing that what’s happening is that the current cannot flow for a brief time then. I tried reducing the dead time but there must be practical limitations of some kind. Theoretically I suppose it’s possible to get it down to a microsecond or something, which would probably be fine, but I think the abstractions that are used when configuring the pwm peripheral settings etc. lead to deviations from that ideal, or perhaps there is some other issue that for practical reasons prevents that.

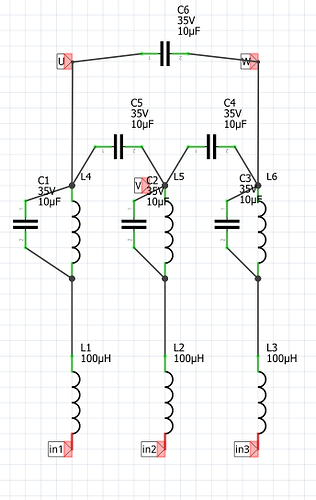

I connected some 100 uh inductors and 10uf ceramic capacitors in the way indicated below, it works :). The first set of inductors gets a bit warm at 150 rads per second, and it consumes considereably more current (about 70 percent more), but that’s not a big deal.

I hope I can optimize the values of the components etc. to improve. Additional stages would allow for less wasted current I think.

Basically my hypothesis is that with only the first set of inductors and the capacitors between the output terminals, the interruption in current into the first inductors leads to a surge in voltage which leads to a surge in current when the mosfets become conducting again. This kick is not damped by the capacitors for some reason, but instead gets passed along.

The function the first stage inductors performs now is just to block the high frequency PWM frequencies. Without them, excessive current flows through the capacitors.

The second set of inductors and capacitors muffles the voltage kick, I think? I haven’t really inspected with my oscilloscope. I’m sure the component values are ridiculous, and this may not be considered a great approach in many ways, but it’s a first step, and seems to validate my hypothesis about the problem being the dead spot.

in1, in2 and in3 got to the driver, the g431 board.

edit: realized I could get rid of about half those components, got rid of l1, l2 and l3 and the capacitors across the U, V and W terminals. It is very slightly louder but not much, and a lot less wasted current, and the l1 etc. inductors were getting a bit warm.