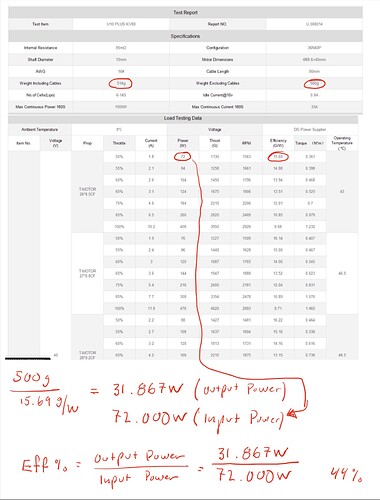

Fundamental assumption error: G/W is the thrust / watt ratio, not motor weight / watt ratio.

The thrust is the propeller vertical aerodynamic thrust, also dependent on the model and type of propeller, so the efficiency listed is irrelevant to your use case. I suggest you use 85% efficiency through-out as a constant.

Let me check the rest. I will post here.

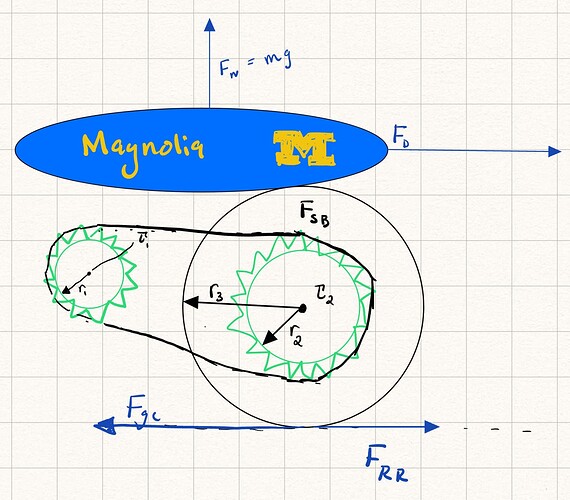

From your rear wheel and gear ratio I get:

265 RPM @ 15 mph

Gear ratio = 9.6

Motor RPM @ 15 mph = 2544

You need a motor that delivers maximum efficiency at 2544 rpm and most efficient at 78W. I calculated from your numbers load of about 72 Watts, using my method, so lets say the truth is around 75 watts.

The torque at 2544 rpm and 75 watts for that system would be 0.28 Nm, so your torque calculation is nearly spot-on, which is excellent.

You need a motor which could produce at least 3000 rpm, preferably 5000 RPM, because motors are usually most efficient in the mid-range of their RPM, and deliver at least about 0.3 Nm at max efficiency. Also it needs to go about 10 times more to accelerate, so max 5000 rpm and 3 Nm.

The motors you showed above are not in that range.

You need a bigger motor.

Most importantly, when calculating efficiency, the rolling resistance at low speeds and laminar flow is about 30/70 so the limiting factor in your system would be the rolling resistance, not transmission + driver efficiency or air drag. You MUST lower the rolling resistance. Also, your rolling resistance of 0.008 is probably a little too high, I would go for 0.005 (or even less, see table below) , which would decrease your wattage to about 50 W and increase the ratio of air drag / RR drag to about 40/60, if you use high quality LRR competition tires. You could get tires down to less than 10W resistance, even down to 7W, which would dramatically improve your efficiency. As you can see, the better tires are more important that a better motor.

Rolling Friction Coefficients

Some typical rolling coefficients:

Rolling Resistance Coefficient

c cl (mm)

0.001 - 0.002 0.5 railroad steel wheels on steel rails

0.001 bicycle tire on wooden track

0.002 - 0.005 low resistance tubeless tires

0.002 bicycle tire on concrete

0.004 bicycle tire on asphalt road

0.005 dirty tram rails

0.006 - 0.01 truck tire on asphalt

0.008 bicycle tire on rough paved road

0.01 - 0.015 ordinary car tires on concrete, new asphalt, cobbles small new

0.02 car tires on tar or asphalt

0.02 car tires on gravel - rolled new

0.03 car tires on cobbles - large worn

0.04 - 0.08 car tire on solid sand, gravel loose worn, soil medium hard

0.2 - 0.4 car tire on loose sand

Cheers,

Valentine