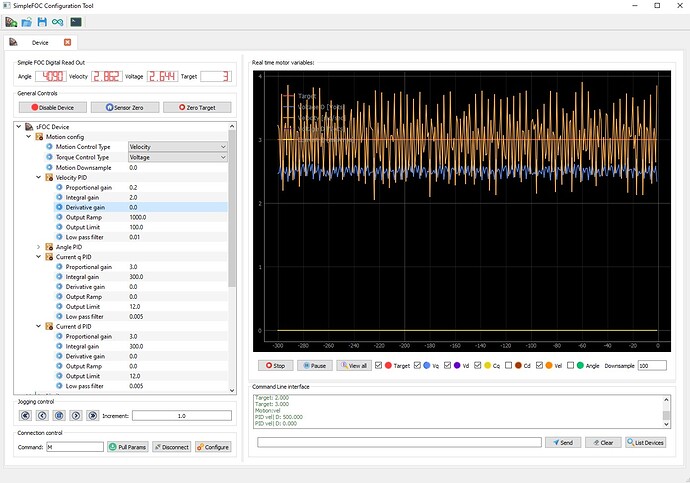

I’ve recently started to use the SimpleFOClibrary but I’m running into some issues when trying to control a Nema 17 with a AS5600 and L298N off of a Nucleo-64. I’m primarily following the example stepper drive code from the examples, but when the motor is turning it sounds just like a bad stepper driver with rough steps and uneven velocity over each rotation. Additionally, it has significant cogging when backdriven. I’m suspecting that there is a lot of performance I’m leaving on the table as a result of my code. The physical wiring of the project is the same as the stepper example except for the AS5600, which I have separately verified to be working. The serial monitor output indicates that the motor gets successfully initiated and returns a magnetic angle and the “Ready” message. Does it look like I’m missing anything in my code that could be causing me these problems? Thank you for the assistance, I’m really excited to have this working!

#include <SimpleFOC.h>

// Stepper motor instance

StepperMotor motor = StepperMotor(50);

// Stepper driver instance

StepperDriver4PWM driver = StepperDriver4PWM(5, 6, 9, 10);

// instance of AS5600 sensor

MagneticSensorI2C encoder = MagneticSensorI2C(AS5600_I2C);

// commander interface

Commander command = Commander(Serial);

void onMotor(char* cmd){ command.motor(&motor, cmd); }

void setup() {

// set voltage for initial config

motor.voltage_sensor_align = 5;

motor.torque_controller = TorqueControlType::foc_current;

// initialize encoder sensor hardware

encoder.init();

//encoder.enableInterrupts(doA, doB);

// link the motor to the sensor

motor.linkSensor(&encoder);

// choose FOC modulation

motor.foc_modulation = FOCModulationType::SpaceVectorPWM;

// power supply voltage [V]

driver.voltage_power_supply = 12;

driver.init();

// link the motor to the sensor

motor.linkDriver(&driver);

// set control loop type to be used

motor.controller = MotionControlType::torque;

motor.torque_controller = TorqueControlType::foc_current;

// controller configuration based on the control type

motor.PID_velocity.P = 0.2;

motor.PID_velocity.I = 20;

motor.PID_velocity.D = 0;

// default voltage_power_supply

motor.voltage_limit = 12;

// velocity low pass filtering time constant

motor.LPF_velocity.Tf = 0.01;

// angle loop controller

motor.P_angle.P = 20;

// angle loop velocity limit

motor.velocity_limit = 50;

// use monitoring with serial for motor init

// monitoring port

Serial.begin(115200);

// comment out if not needed

motor.useMonitoring(Serial);

// initialise motor

motor.init();

// align encoder and start FOC

motor.initFOC();

// set the initial target value

motor.target = 1;

// define the motor id

command.add('M', onMotor, "motor");

// Run user commands to configure and the motor (find the full command list in docs.simplefoc.com)

Serial.println(F("Motor commands sketch | Initial motion control > torque/voltage : target 2V."));

_delay(1000);

}

void loop() {

// iterative setting FOC phase voltage

motor.loopFOC();

// iterative function setting the outter loop target

// velocity, position or voltage

// if tatget not set in parameter uses motor.target variable

motor.move();

// user communication

command.run();

}