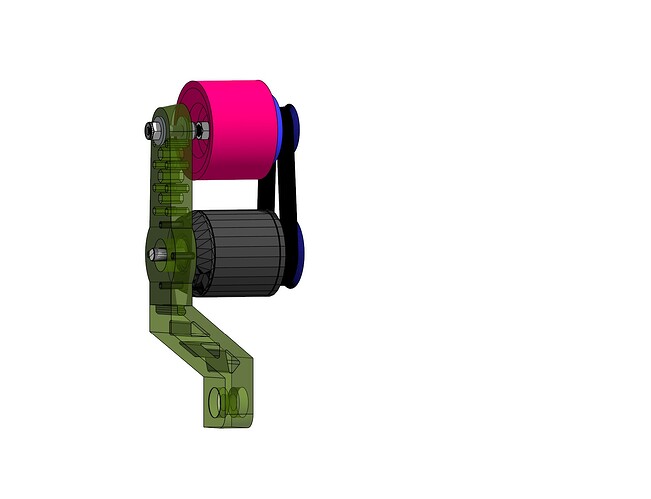

6368 outrunner on broom w. PU wheel (Molded)

I have these 72mm wheels. And I do have a 3mm pitch belt. I think it should be possible to pre-drill PU …

The sensor magnet can be placed on the shaft. Most importantly it shall be able to brake the rider. On quad skates it can be quite sketchy to brake when street skating, going down hills…

It will be wurth a shot, to see if the traction between bike wheel and longboard wheel can drive a bike? By way of strong springs pulling the wheels together.

Hmm… suddenly one can charge a phone while biking.

Maybe the smartest is to use slicks (tires) with the smoothy skate surface. Ideally the tire and wheel should have same pattern, like a gear.

There should be a 8mm threaded rot going through the arm and longboard wheel, where the springs/rubber_band should be attached to the frame.

This is with the 68mm outrunner.

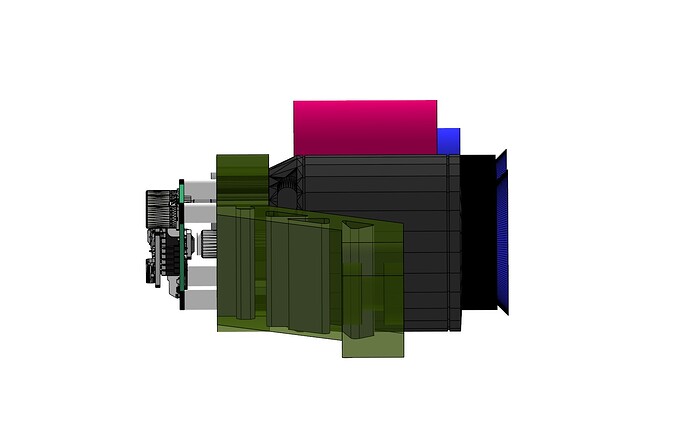

This is printed in two parts. I believe it is functional. The gearing will match a re-winding of around 50-60 KV. The bike wheel top speed should be around 250-300 rpm. So we should aim for around 2500-3000 rpm on the motor, depending on gearing etc.

Just rediscovered printing with 0.8mm nozzle. 0.8mm really does make string walls/structures, fast.

Yes, those are some nasty wheel bites, I strained a rib on that one…

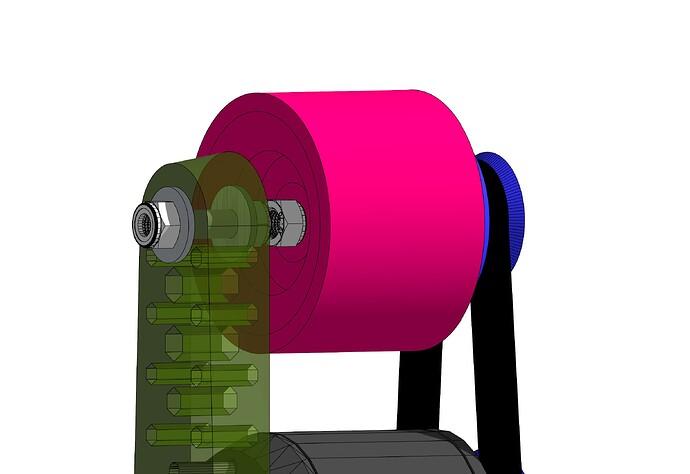

You can drill 3mm self-cutting screws into PU (78A) wheels. Getting the gear centered is a challenge, maybe if the wheel is locked in on the fitted bearings and 8mm Shaft, it will help align it.

The challenge, of course, is to transfer the motor power to the wheel, in a optimal manor, while maintaining low current draw. So a rewind to lower KV is mandatory, if the goal is to keep it withing the legal 250W nominal power consumption. 250W translated in a good way will be a decent overall input to the drivetrain. Unless you want to trough aloha amps @IT

The wheel will need to be tightened to the bike frame, the Shaft is supposed to stick out like that.

This is with a 2:1 gearing so 1200-1500 rpm on the motor should do.

The overall motor to wheel gearing is around 1:5. The equivalent bike gearing would be 28teeth on the front sprocket and 140t on the rear.

What’s the need for the pulley? Could you print a thing that went around the outside of the motor and connected directly to the shaft of the motor and got the same torque to speed ratio? Maybe give it a pattern to increase friction. I have had good success with printing in TPU as well, you could print a sleeve out of TPU and glue it on with shoe goo.

I think it’s cool to use my longboard wheel, which I suppose is subjective. The belt drive allows for gearing it down some…

Awesome! hope your wheels are true…

How do you keep wheel in contact? Do you have a preload somewhere that pushes the drive wheel down into the bike wheel?