For those of you interested in the driver, an update. Got some time over the weekend, here is the result.

Setup:

Software:

Windows Server 2019 Host.

VMWare Workstation Pro 16

Windows Server 2019 Guest.

USB Pass-trough from host to guest

Arduino clean install on guest

Simple FOC clean git pull

Wittecactus instructions for board deployment on Arduino

Hardware:

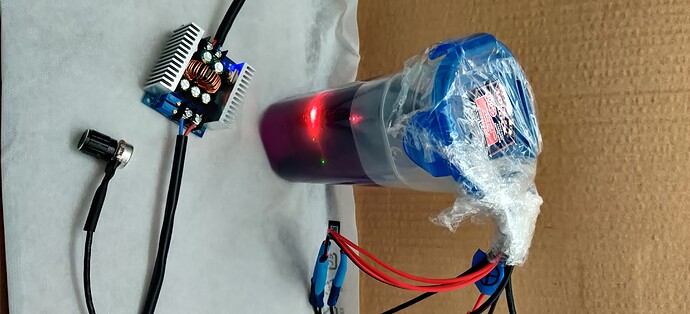

B-G431B-ESC1 Board

12 V Power Source

100 MHz Oscilloscope

Connect and turn blue potentiometer on DB. This is the expected result. You will see the control wave between any of the three pole wires on the oscilloscope. With the potentiometer, you control the speed of the motor. Oscilloscope waveform will change.

You must modify the sample code below to scale the speed else gruesome injuries may occur if you decide to connect a live motor! Also must fix motor to solid testbed unless you want to decapitate yourself.

The board reverse voltage protection works fine, I connected for 30sec reverse polarity to test, it just got really hot and nearly de-soldered. The Transil on the board prevents damage in case of reverse polarity at the input side for a low time. Not sure how low is low time, but it drew 4 Amps and in 30 sec noticeably overheated. YMMV. If you have good liquid cooling it may survive for a while.

The board is a dev board. The layout is rather poor. The board is dense and really hard to solder, I needed a microscope. If you need high current you will need copper solder boots and liquid cooling. I mean dunk it in dielectric coolant (fluorinert, novec, etc). Even idle the board draws 0.1A which will overheat it really fast. Whoever designed the board didn’t allow for proper heat-sinks and screw boots, only solder. But for $18, I can’t complain, this is a terrific deal.

Apologies for the literal test bed on the pic, covid forced me to work from home and I can’t get to my nice lab at work.

If I have time I will post the coolant solution.

I’ll try to check the others solutions I saw someone did a current control, will try.

It’s a great board and a great price point.

Sample absolute minimal code for velocity control via daughter-board potentiometer:

#include <SimpleFOC.h>

// NUMBER OF POLE PAIRS, NOT POLES

BLDCMotor motor = BLDCMotor(7);

// MUST USE 6PWM FOR B-G431 DRIVER

BLDCDriver6PWM driver = BLDCDriver6PWM(PHASE_UH, PHASE_UL, PHASE_VH, PHASE_VL, PHASE_WH, PHASE_WL);

void setup() {

// driver config

// power supply voltage [V]

driver.voltage_power_supply = 12;

driver.init();

// link the motor and the driver

motor.linkDriver(&driver);

// limiting motor movements

motor.voltage_limit = 3; // [V]

motor.velocity_limit = 1024; // [rad/s]

// open loop control config

motor.controller = MotionControlType::velocity_openloop;

// init motor hardware

motor.init();

}

void loop() {

motor.move(analogRead(POTENTIOMETER));

}

. I managed to get the AS5048A magnetic sensor working in PWM mode as well (connected to the HALL1 pin) by creating a new sensor type heavily based on the existing MagneticSensorAnalog .cpp and .h files. I am getting some oscillations in closed loop velocity/position control modes at low speeds, but I imagine that is mostly due to lack of proper tuning and a relatively high kv motor (650kv).

. I managed to get the AS5048A magnetic sensor working in PWM mode as well (connected to the HALL1 pin) by creating a new sensor type heavily based on the existing MagneticSensorAnalog .cpp and .h files. I am getting some oscillations in closed loop velocity/position control modes at low speeds, but I imagine that is mostly due to lack of proper tuning and a relatively high kv motor (650kv).

) is a bad idea. I am testing running an 800W motor off it.

) is a bad idea. I am testing running an 800W motor off it.